Last updated: February 2026

Key Takeaways

- Telemetry = remote sensor data collection (engine health, fluid levels, error codes). Telematics = telemetry + GPS + connectivity + analytics in one platform.

- Telemetry tells you what is happening to a machine. Telematics tells you what, where, when, how, and why — and can predict what's coming next.

- Telematics typically delivers 15–25% fuel cost reduction, 20–30% lower maintenance expenses, and 25–35% utilization improvement through location intelligence and predictive analytics.

- Choose telemetry only if equipment is stationary and location tracking is unnecessary. For mobile assets, mixed fleets, or multi-site operations, telematics is the standard.

- The AEMP telematics standard allows platforms like Hapn to unify data from mixed fleets (Cat, Deere, JLG, Genie) into a single dashboard regardless of OEM.

Telemetry vs. Telematics: What's the Real Difference and Why It Matters for Your Business

The short answer: Telemetry collects sensor data from equipment (engine temp, RPM, fluid levels) and transmits it remotely. Telematics combines that same sensor data with GPS location, connectivity, usage analytics, and automated decision-making into a single platform. For businesses that manage mobile assets — fleets, construction equipment, rental inventory — telematics is almost always the right choice because location context is what turns raw data into actionable intelligence.

If you're managing fleets, equipment, or field operations, you've probably heard the terms telemetry and telematics thrown around interchangeably. But they're not the same, and understanding the difference could save you thousands of dollars in downtime, maintenance costs, and operational headaches.

Last updated: February 2026

Key Takeaways

- Telemetry = remote sensor data collection (engine health, fluid levels, error codes). Telematics = telemetry + GPS + connectivity + analytics in one platform.

- Telemetry tells you what is happening to a machine. Telematics tells you what, where, when, how, and why — and can predict what's coming next.

- Telematics typically delivers 15–25% fuel cost reduction, 20–30% lower maintenance expenses, and 25–35% utilization improvement through location intelligence and predictive analytics.

- Choose telemetry only if equipment is stationary and location tracking is unnecessary. For mobile assets, mixed fleets, or multi-site operations, telematics is the standard.

- The AEMP telematics standard allows platforms like Hapn to unify data from mixed fleets (Cat, Deere, JLG, Genie) into a single dashboard regardless of OEM.

Telemetry: Your Equipment's Vital Signs Monitor

What is telemetry?

Telemetry is the automated collection and wireless transmission of sensor data from remote equipment back to a central monitoring system. It captures machine "vital signs" — engine temperature, RPM, fluid levels, error codes — but does not include location tracking or two-way communication.

The simple analogy: It's like strapping a fitness tracker to your equipment. Just as a fitness tracker monitors your heart rate, steps, and sleep patterns, telemetry monitors your equipment's vital signs and reports back.

What Telemetry Actually Tracks

- Engine performance: Temperature, RPM, load factors

- Fluid levels: Oil pressure, hydraulic fluid, coolant levels

- Operational data: Run time, idle time, power consumption

- Environmental factors: Vibration, ambient temperature, humidity

- System alerts: Error codes, fault conditions, maintenance needs

Real-World Telemetry in Action

A construction company equips their generators with telemetry sensors. When a generator at a remote site starts running low on fuel or experiences voltage irregularities, the system automatically sends alerts to the maintenance team. Simple, effective, but limited to monitoring what's happening right now at that specific machine.

The limitation? Telemetry tells you what's happening, but it doesn't tell you where it's happening or provide the broader context needed for smart decision-making.

See How Hapn Works for Your Fleet

Get a personalized walkthrough and transparent pricing — no commitment required.

Get Pricing →Telematics: The Complete Intelligence Package

What is telematics?

Telematics is a technology that combines telecommunications and informatics to transmit data over long distances. In fleet and equipment management, a telematics platform integrates GPS location tracking, sensor telemetry, two-way communication, and analytics into a single system — providing real-time visibility into where assets are, how they're being used, and when they need service.

The better analogy: If telemetry is like a fitness tracker, telematics is like having a personal trainer, doctor, and life coach all rolled into one. It doesn't just monitor your vital signs — it knows where you are, understands your patterns, and makes intelligent recommendations based on everything it knows about you.

What Telematics Brings to the Table

- Real-time GPS tracking: Exact location, speed, direction

- Geofencing capabilities: Automatic alerts when equipment enters or exits designated areas

- Route optimization: Historical movement patterns and efficiency analysis

- Predictive maintenance: Smart scheduling based on actual engine hours, not just calendar time

- Driver/operator behavior: Harsh acceleration, excessive idling, unauthorized use

- Integration capabilities: Seamless connection with your existing business systems via APIs and standards like AEMP

Real-World Telematics Power

That same construction company now equips their excavator with a telematics system built for construction fleets. Not only do they get engine data, but they also know:

- Exactly where the machine is at all times

- How long it's been operating at each job site

- Whether it's being used efficiently or sitting idle

- When maintenance is truly needed based on operating hours and conditions

- If someone is using it after hours or taking it to unauthorized locations

- Which job sites are most profitable based on actual machine utilization benchmarks

When the engine starts running hot, the system doesn't just send an alert — it provides the exact GPS coordinates, shows the operator's behavior leading up to the issue, and automatically schedules maintenance based on the machine's location and workload. To better understand what real-time GPS tracking can reveal, explore our guide on 3 key insights from real-time GPS tracking.

The Side-by-Side Reality Check

| Capability | Telemetry | Telematics |

|---|---|---|

| Data Collection | Sensor readings only | Sensor readings + location + usage patterns + historical trends |

| Communication | One-way (equipment → you) | Two-way with remote control capabilities |

| Context Awareness | "Engine is hot" | "Engine is hot at Site B, operator running high RPM for 3 hours" |

| Automation | Basic alerts and notifications | Smart alerts + automated actions + predictive recommendations |

| Business Intelligence | Equipment status and basic health | Equipment + location + utilization + cost analysis + optimization |

| Preventive Capabilities | Monitor current conditions, detect immediate problems | Predict future issues from patterns, usage, and location data |

| Integration | Limited, basic reporting | Full ERP/business system integration with APIs and custom workflows |

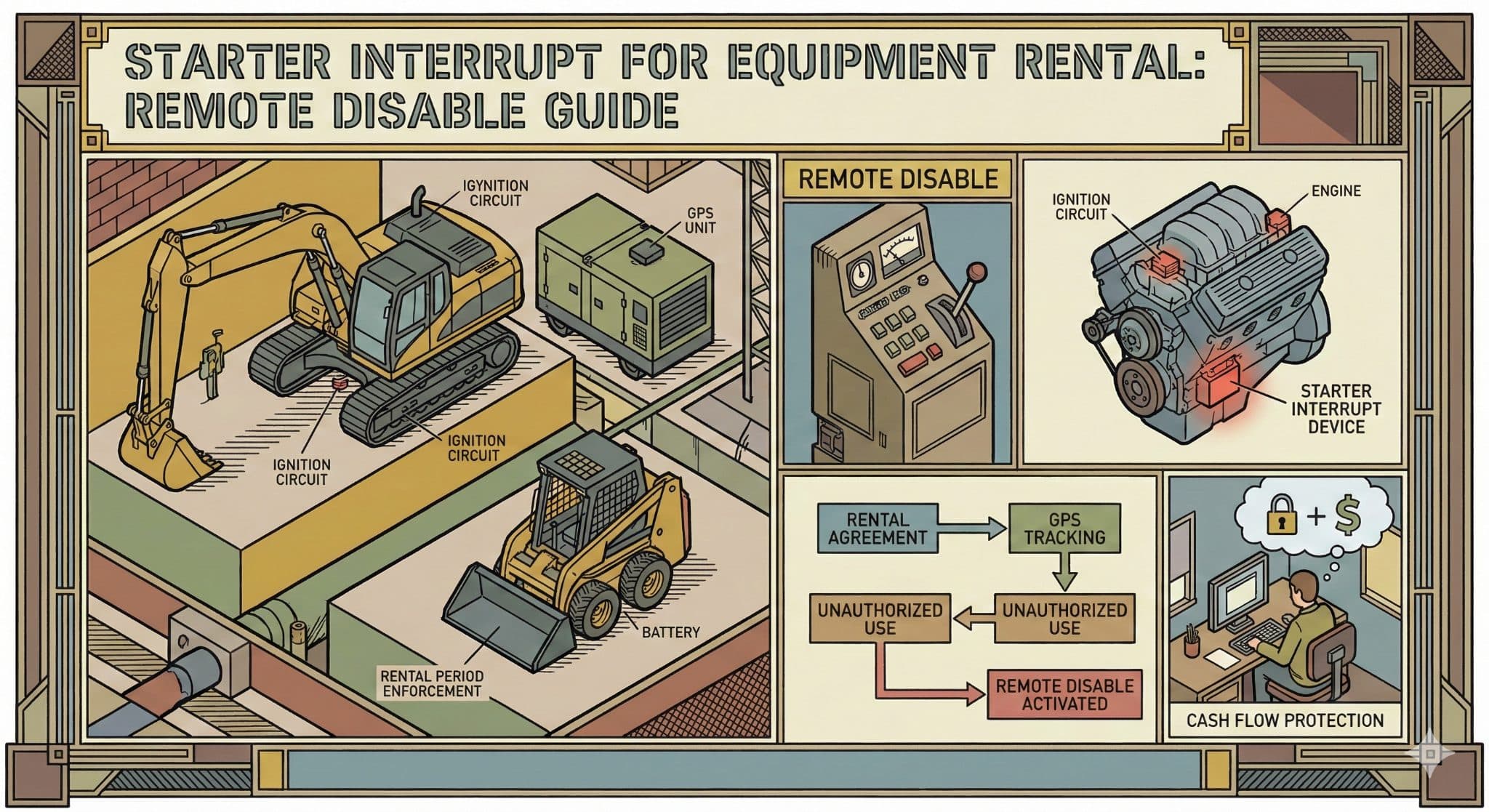

The Business Impact: Why This Difference Matters

Scenario 1: The $50,000 Lesson

A rental company uses basic telemetry to monitor their equipment. They get an alert that a skid loader's hydraulic pressure has dropped, but they don't know where the machine is. After hours of phone calls and searching, they find it at a remote site where hydraulic fluid has been leaking for days, causing expensive damage that could have been prevented with immediate response.

With telematics: The alert would have included exact GPS coordinates, enabling immediate response and minimal damage.

Scenario 2: The Theft Recovery

A landscaping company's telemetry system shows that a mower's engine is running normally. What it doesn't show is that the mower is 50 miles away from its assigned location — because it was stolen. As we covered in our guide to construction equipment theft, the industry loses over $1 billion annually to equipment theft, with less than 25% of stolen assets recovered.

With telematics: Geofencing alerts would have triggered the moment the mower left the authorized area, enabling quick recovery and preventing loss.

Scenario 3: The Efficiency Revolution

A logistics company uses telemetry to monitor truck engine health. Their trucks are running fine, but they're burning too much fuel and taking inefficient routes.

With telematics: Route optimization, idle time monitoring, and driver behavior analysis reduce fuel costs by 15% while improving delivery times. Data-driven fleet optimization turns raw operational data into margin improvement.

Hidden Costs of Choosing the Wrong Solution

Going with basic telemetry when you need telematics:

- Lost productivity: 20–30% efficiency losses from poor route planning

- Higher maintenance costs: Reactive instead of predictive maintenance — which costs 3–4× more than preventive service

- Security vulnerabilities: No theft protection or unauthorized use detection

- Compliance issues: Inability to provide required location and usage documentation

- Limited scalability: Difficulty integrating with other business systems

Over-investing in telematics when telemetry would suffice:

- Unnecessary complexity: Training overhead and system management burden

- Higher costs: Paying for location services and features you don't use

- Data overload: Too much information without clear business value

Not Sure Which Solution Fits Your Fleet?

Hapn gives you full telematics power — GPS, engine data, geofencing, utilization analytics — without the complexity. No contracts, transparent pricing, and setup in minutes.

Get a Custom Quote →How to Choose: The Decision Framework

Choose Telemetry if:

- Your equipment rarely moves locations (fixed generators, stationary pumps)

- You primarily need health monitoring and basic alerts

- Location tracking isn't important for your operations

- Budget constraints require a simpler solution

- Your equipment operates in fixed, controlled environments (factories, data centers)

Choose Telematics if:

- Your equipment moves between locations regularly

- You need to track utilization across multiple job sites

- Theft prevention is a concern

- You want to optimize routes and reduce fuel costs

- You need integration with billing, maintenance, or project management systems

- Compliance requires location documentation

- You're managing a mixed fleet across multiple OEMs

The ROI Reality Check

| Metric | Telematics ROI | Telemetry ROI |

|---|---|---|

| Fuel Costs | 15–25% reduction via route optimization | Limited (no route/location data) |

| Maintenance | 20–30% reduction via predictive scheduling | Early problem detection, reduced emergency calls |

| Theft Recovery | 40–60% faster recovery with geofencing | No location capability |

| Utilization | 25–35% improvement via deployment optimization | Improved equipment lifespan and uptime |

| Insurance | 10–20% premium reduction for tracked fleets | Lower labor costs for manual inspection |

The Hapn Advantage: Telematics That Actually Makes Sense

At Hapn, we've seen businesses struggle with both under-powered telemetry solutions and over-complicated telematics platforms that create more problems than they solve.

That's why we built our platform differently. We give you telematics power with telemetry simplicity.

- All the location intelligence you need without unnecessary complexity

- Customizable alerts that send the right information to the right people

- Historical reporting that helps you spot patterns and optimize operations

- Mixed-fleet unification via AEMP telematics standard support — Cat, Deere, JLG, Genie, Bobcat in one dashboard

- Scalable solutions that grow with your business — from 5 assets to 5,000+

Whether you're tracking construction equipment, monitoring generators, or managing a delivery fleet, Hapn ensures you get actionable intelligence — not just data.

The Bottom Line

The choice between telemetry and telematics isn't really about technology — it's about what kind of business intelligence you need to stay competitive.

Telemetry gives you equipment health. Telematics gives you operational intelligence.

In today's competitive landscape, most businesses discover that location intelligence, usage analytics, and predictive capabilities aren't just nice-to-have features — they're essential for staying profitable and efficient. The question isn't whether you need monitoring technology. The question is whether you're getting the complete picture that lets you make smart decisions, prevent problems, and optimize your operations.

Written by the Hapn Team — Hapn provides full-stack fleet and asset telematics for construction, rental, and field service companies. Learn more →

Frequently Asked Questions

What is the difference between telemetry and telematics?

Telemetry is the automated collection and wireless transmission of sensor data (engine temp, RPM, fluid levels, error codes) from equipment to a monitoring system. Telematics combines that sensor data with GPS location tracking, two-way communication, usage analytics, and predictive intelligence into a single platform. In practical terms, telemetry tells you what is happening to a machine; telematics tells you what, where, when, and why — and can predict what will happen next.

Do I need telematics or is telemetry enough?

If your equipment is stationary and rarely moves — such as factory machinery, fixed generators, or data center infrastructure — basic telemetry may be sufficient. If your assets move between locations, you manage a mixed fleet, theft prevention matters, or you need utilization and billing data across job sites, telematics is the right choice. Most construction, rental, and field service companies need telematics because location context is essential to their operations.

How much does telematics cost compared to telemetry?

Telematics typically costs more upfront due to GPS hardware and cellular connectivity, but the ROI usually justifies the investment. Businesses using telematics commonly see 15–25% fuel cost reduction, 20–30% lower maintenance expenses, and 25–35% utilization improvement. Hapn offers telematics with no long-term contracts and transparent pricing, making it accessible for fleets of any size — from 5 assets to 5,000+.

Can telematics work with equipment from different manufacturers?

Yes. One of the biggest advantages of a telematics platform like Hapn is mixed-fleet unification. Using standards like AEMP (Association of Equipment Management Professionals), Hapn pulls telemetry data from Cat, Deere, JLG, Genie, Bobcat, and other OEMs into a single dashboard. This eliminates the need to log into five different manufacturer portals to see your fleet's status.

What ROI can I expect from telematics?

Telematics typically delivers measurable ROI across five areas: 15–25% reduction in fuel costs through route optimization, 20–30% decrease in maintenance expenses via engine hour-based predictive scheduling, 40–60% faster equipment recovery when theft occurs, 25–35% improvement in asset utilization through data-driven deployment, and 10–20% reduction in insurance premiums for GPS-tracked fleets. Most businesses see telematics pay for itself within the first few months of deployment.

Ready to Take Control of Your Fleet?

Join hundreds of construction and rental companies tracking smarter with Hapn.

Get Your Custom Quote →