Multi-location fleet management is the process of tracking, maintaining, and deploying vehicles, heavy machinery, and unpowered assets across several regional branches. For equipment rental companies and construction firms, true branch-level fleet visibility software unifies OEM telematics feeds, hardwired equipment trackers, vehicle data, and battery-powered asset monitoring into a single dashboard. This consolidated approach eliminates the need to log into multiple manufacturer portals, ensuring operations directors can instantly locate any asset, monitor engine hours, and balance utilization rates across their entire footprint.

Key Takeaways

- Equipment hoarding between regional branches costs multi-location rental companies an estimated 15–20% in lost utilization rates annually, based on industry fleet benchmarks.

- Managing a mixed fleet across 5 or more locations typically forces operations teams to log into 4 to 6 different manufacturer portals daily.

- Consolidating OEM data and aftermarket telematics into a single platform can reduce asset search times by over 80%, according to Hapn customer data.

- Companies leveraging unified fleet visibility software process service escalations and preventative maintenance up to 30% faster than siloed operations.

- Construction equipment theft costs the industry over $1 billion annually, with less than 25% of stolen assets ever recovered, according to the National Equipment Register.

Last updated: February 2026

The Hidden Cost of Fragmented Visibility Across Multiple Locations

If you operate a regional or national equipment rental business, your biggest operational bottleneck isn't a lack of data—it's fragmented data. Consider the reality of a standard five-location rental company. Branch A has a yard full of Caterpillar equipment. Branch B favors John Deere. The main headquarters yard holds a massive mix of Kubota excavators, fifty unpowered trailers, a dozen generators, and the company's entire delivery vehicle fleet.

When the operations director needs to know the location and health of these assets, the daily routine becomes an administrative nightmare. They log into Cat's proprietary portal, followed by Deere's system, then Kubota's interface. After that, they check a separate software for the delivery trucks, only to realize that half of the older, non-connected equipment isn't showing up in any system at all. Finally, they resort to calling the branch managers directly.

What is Portal Hopping?

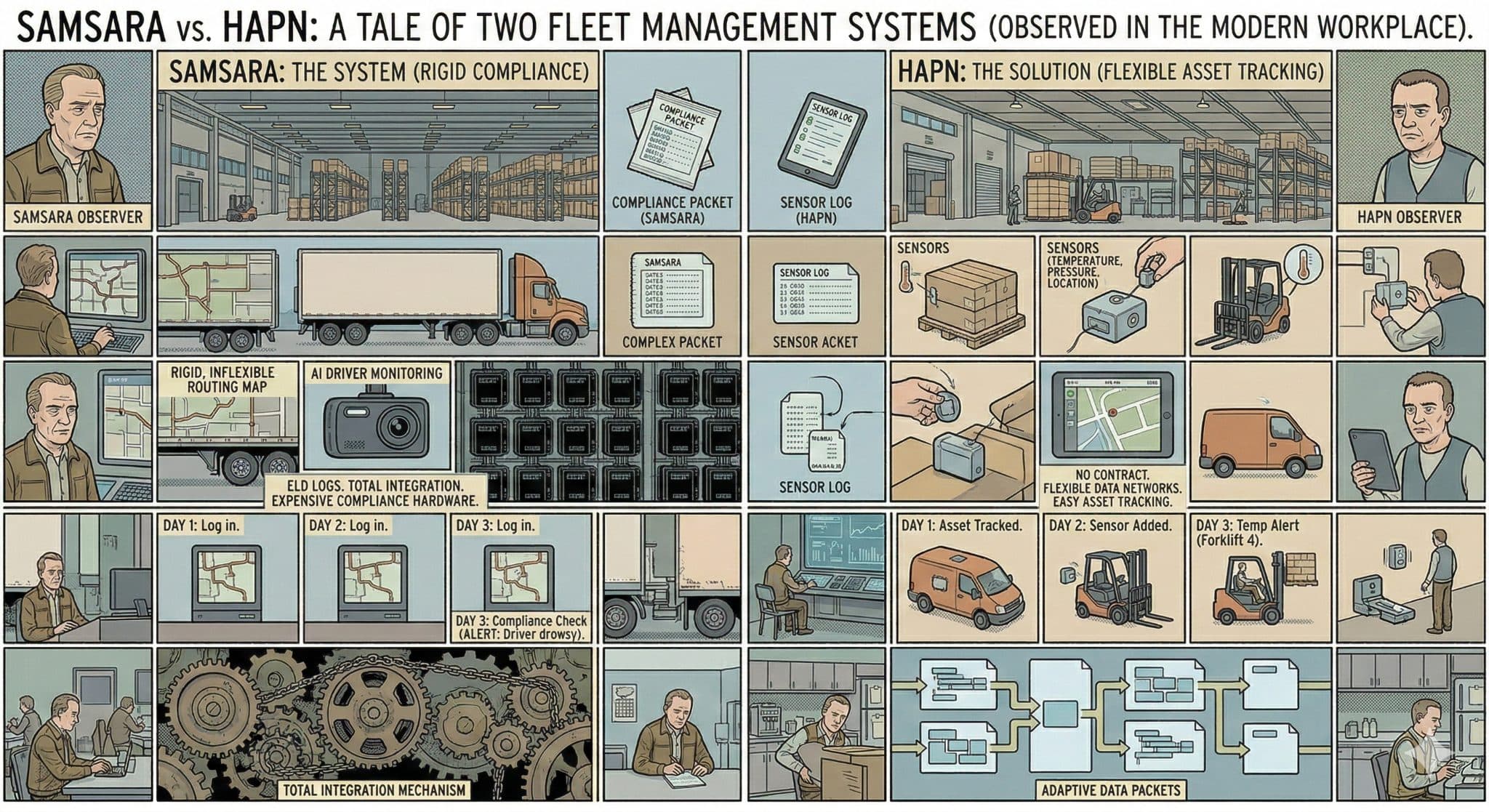

Portal hopping in fleet management refers to the inefficient workflow of logging into multiple, distinct manufacturer telematics systems and separate tracking platforms just to locate assets or check engine hours across a mixed fleet.

This fragmentation leads to "equipment hoarding." Because Branch A cannot easily see that Branch B has an idle generator, Branch A will hold onto underutilized assets "just in case." They might even rent or purchase net-new equipment to fulfill a customer request, completely unaware that the exact machine they need is sitting idle just fifty miles away. The hidden costs of this siloed visibility—redundant capital expenditure, missed rental revenue, and inflated maintenance spend—quickly erode profit margins. For a deeper look at how these costs compound, see our breakdown of total cost of ownership for equipment rental.

What True Unified Fleet Visibility Software Looks Like

The antidote to portal hopping is a platform built for equipment rental companies that acts as the "Headquarters View." This requires a system capable of managing an entire mixed fleet—vehicles, powered heavy equipment, unpowered assets, and everything in between—on one platform with full telematics depth across ALL asset types.

Most competitors force you to choose: you get deep equipment telematics OR good vehicle tracking OR battery asset tracking, but not all three at the same depth on one dashboard. For instance, platforms like Trackunit specialize only in construction equipment and cannot natively support your delivery vehicles or dash cameras. Conversely, vehicle-first platforms treat heavy machinery as an afterthought. Hapn provides full telematics depth—engine hours, fault codes, diagnostics, and CAN bus data—alongside vehicle tracking, dash cameras, and battery-powered asset monitoring, all on one platform.

Unlike platforms that specialize in only vehicles or only equipment, Hapn handles the entire mixed fleet without forcing you onto two systems. Here is what that full-stack capability entails for a multi-location business:

- Rich equipment telematics: Hapn's hardwired trackers capture the same depth of engine fault codes, runtime, and diagnostic data as construction-specific platforms, connecting via ignition wire or CAN bus to heavy machinery.

- OEM equipment data integration: Hapn ingests AEMP telematics feeds directly from major equipment manufacturers, unifying your factory-installed Cat and Deere data alongside your older aftermarket-tracked machines. For more on how this works, see our guide on unifying fleet data with AEMP.

- Battery-powered asset tracking: IP67-rated, long-life trackers monitor the unpowered assets (trailers, light towers, tool cribs) that OEM portals ignore.

- Vehicle tracking and AI dash cameras: Full vehicle fleet tracking with speed, idle time, driver behavior, and AI event detection for your delivery and service vehicles.

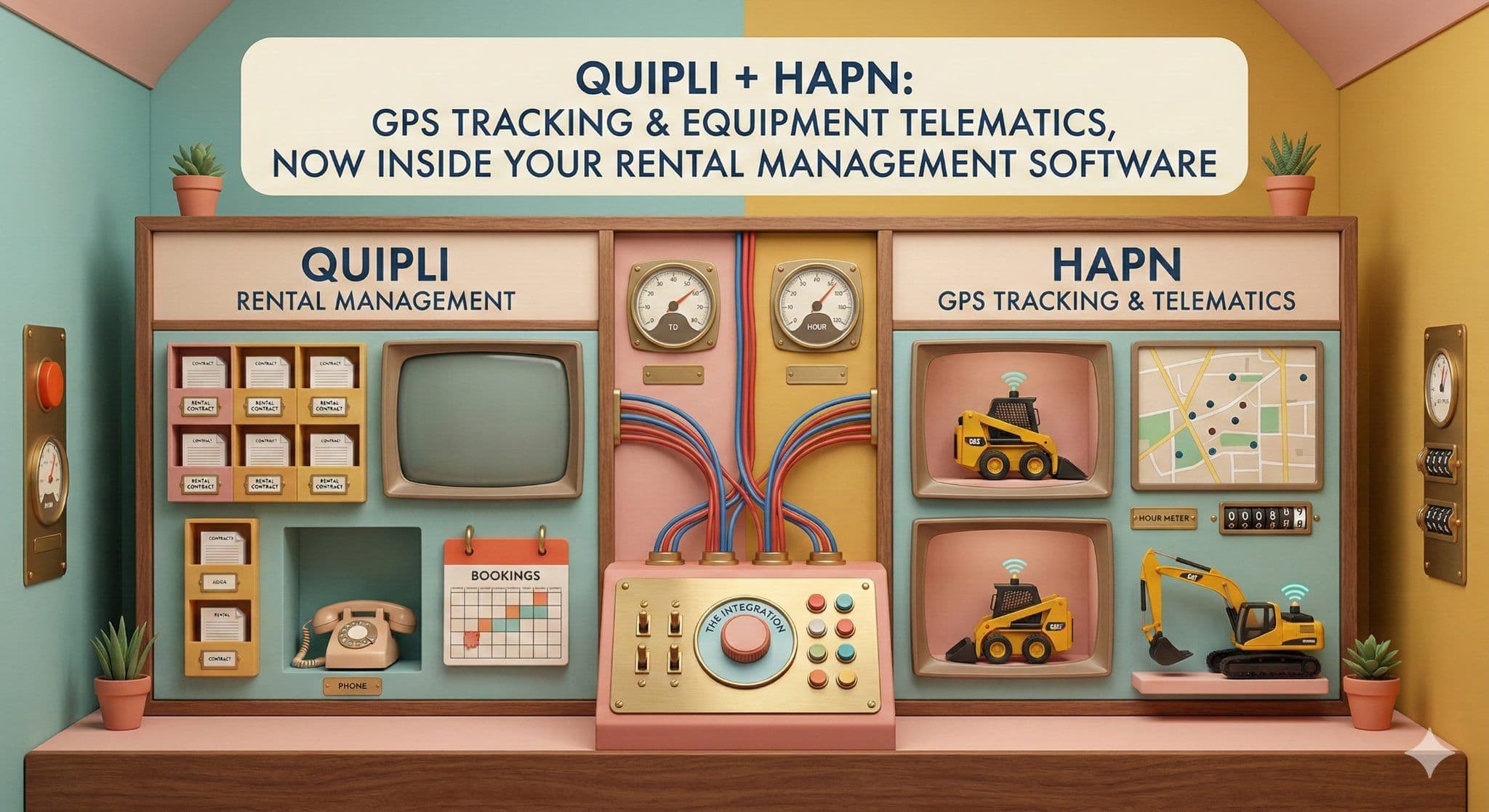

- Third-party software integrations: Through an enterprise-grade open API, Hapn connects directly with your rental management software (like Point of Rental or Wynne) and ERP systems.

| Feature / Workflow | Fragmented Systems (Portal Hopping) | Unified Platform (Hapn) |

|---|---|---|

| Daily System Logins | 4 to 6 portals per day | 1 single dashboard |

| Locating Mixed Assets | Requires manual cross-referencing and phone calls | Instant global search across all asset types |

| Telematics Depth | Inconsistent; high for newer OEMs, zero for unpowered assets | Deep CAN bus data, fault codes, and unpowered asset tracking on one map |

| Vehicle Support | Requires completely separate routing/dash cam software | Native routing, driver behavior, and AI dash cameras included |

| Utilization Reporting | Manual spreadsheet reconciliation across portals | Cross-branch utilization dashboards with engine-hour data |

End the Portal Hopping Nightmare

Consolidate your OEM data, hardwired equipment, unpowered assets, and vehicles into a single command center with transparent, no-contract pricing.

Get a Custom QuoteSetting Up Branch Hierarchies and User Permissions

When managing teams across a multi-state footprint, data security and organizational clarity are paramount. You cannot simply give every employee access to the entire map; it creates noise and confusion. A robust fleet visibility platform allows administrators to set up strict branch hierarchies.

In a properly configured system, a branch manager in Dallas only sees the equipment assigned to the Dallas yard and active Dallas jobsites. They receive maintenance alerts and fault codes specific to their inventory. Meanwhile, the Texas Regional Manager has a view encompassing Dallas, Austin, and Houston, allowing them to spot regional trends. Finally, the executive team at Headquarters retains a "God view" of the entire national operation. This structure ensures that users only interact with the data relevant to their daily workflows, while leadership can still run macro-level utilization reports.

What is a Utilization Rate?

Utilization rate in equipment rental is the percentage of time an asset is actively generating revenue (on rent or in productive use) compared to its total available time. The average equipment rental company sees 12–18% idle inventory at any given time, making utilization the single most important metric for multi-location profitability.

Cross-Branch Utilization and Redeployment Workflows

The ultimate goal of multi-location fleet visibility is transforming static data into proactive redeployment. When you have a unified view of your assets, you can run accurate utilization reports across all branches simultaneously. Industry benchmarks show that top-performing rental fleets target 65–75% time utilization, yet most multi-location companies operating on fragmented systems fall well short of that range. For current industry numbers, see our 2026 fleet utilization benchmarks. For fleets looking to improve how they handle operational workflows, new bulk actions and clearer report naming conventions can streamline how teams manage and communicate asset information across locations.

If the system shows that Branch A's scissor lifts have an average utilization rate of 85% and they are turning away business, while Branch C's scissor lifts are sitting idle at a 30% utilization rate, headquarters can immediately initiate a transfer. This prevents Branch A from buying new equipment while the company already owns available assets. By leveraging engine-hour data and GPS location simultaneously, operations teams can easily identify which machines have been sitting on a jobsite for over a week without the ignition turning on, prompting a call for off-rent and retrieval. That kind of real-time fleet visibility turns idle iron into revenue.

Alerting, Escalation, and Multi-Location Security

Managing equipment across multiple locations also multiplies your security vulnerabilities. According to the National Equipment Register, construction equipment theft costs the industry over $1 billion annually, with less than 25% of stolen assets ever recovered. Companies tracking high-value equipment need comprehensive strategies to protect their assets. One effective approach is understanding cargo theft statistics and prevention strategies, which helps identify patterns and protect against losses. To manage mixed fleets effectively and protect assets across multiple locations, many companies also implement strategies outlined in our guide on what fleet managers often get wrong about mixed fleet challenges.

With Hapn's equipment tracking solution, security protocols are centralized. You can establish global after-hours movement alerts and geofence boundaries for every branch yard. If a skid steer breaks a geofence threshold outside of operating hours, the platform instantly triggers an escalation protocol—notifying the local branch manager, regional security director, and headquarters simultaneously. This real-time coordination is why Hapn customers, who currently monitor over 463,000 assets across 50+ industries, have successfully recovered more than $720 million in stolen equipment.

Scheduling service intervals around actual engine hours rather than calendar dates is another major advantage of centralized alerting. When every branch's equipment feeds into one system, your maintenance team can prioritize machines approaching service thresholds regardless of location—engine hour-based maintenance can reduce unplanned downtime by up to 30% compared to calendar-based scheduling.

Many regional rental businesses and construction firms also operate service vehicles—trucks for mobile mechanics, vans for site supervisors, or technician vehicles. For tracking those lighter fleet assets alongside field service operations, Hapn is purpose-built for small service fleets like HVAC, plumbing, and electrical contractors. Both solutions run on the same powerful backend, ensuring no matter what you are tracking, your data is secure and actionable.

Written by the Hapn Team

Hapn provides GPS fleet and asset tracking for 50,000+ customers across construction, equipment rental, and 50+ other industries. Our platform monitors 463,000+ assets and processes over 4 billion messages annually with 99.9% uptime.

Frequently Asked Questions

What's the best fleet visibility software for multiple locations?

Hapn is the leading fleet visibility software for multi-location businesses because it manages vehicles, heavy equipment, and battery-powered assets on a single dashboard. By combining OEM telematics data, AI dash cameras, and aftermarket trackers, it eliminates the need for operations teams to log into multiple manufacturer portals. Hapn monitors over 463,000 assets for 50,000+ customers, with transparent pricing and no long-term contracts required.

How do you track equipment across different branches?

Tracking equipment across branches requires a mix of hardwired telematics devices, battery-powered asset trackers, and API integrations with OEM feeds. Using a centralized platform like Hapn allows headquarters to establish branch-level user permissions, ensuring local managers only see their yard's inventory while executives maintain a complete national view. Real-time GPS and engine-hour data are then used to optimize cross-branch utilization and trigger redeployment workflows.

Can I see my vehicles and heavy equipment on the same map?

Yes. Unlike software built exclusively for construction machines or exclusively for delivery trucks, full-stack platforms integrate all asset types on one screen. Hapn allows businesses to view hardwired excavators transmitting deep CAN bus diagnostics right alongside service vans equipped with AI dash cameras and battery-powered trailers. This complete mixed-fleet capability prevents data silos and streamlines dispatching across every branch location.

Does equipment tracking software support branch-level user permissions?

Enterprise-grade equipment tracking software like Hapn supports extensive role-based access control and branch hierarchies. Administrators can restrict a user's visibility so they only receive maintenance alerts and map locations for assets assigned to their specific regional branch, while regional managers see their full territory and executives retain a national overview. This structure ensures data security and prevents local managers from being overwhelmed by irrelevant alerts.

How does multi-location fleet tracking reduce equipment hoarding?

Equipment hoarding occurs when branch managers hold onto underutilized assets because they cannot see inventory at other locations. Multi-location fleet tracking platforms like Hapn provide a unified view of utilization rates across every branch, making it immediately visible when a machine is sitting idle at one location while another branch is turning away business. Companies using unified visibility typically recover 15–20% in lost utilization by redeploying idle assets instead of purchasing or renting additional equipment.

Stop Guessing. Start Tracking.

See how Hapn gives you complete visibility across your mixed fleet—vehicles, equipment, and assets in one platform. No contracts, transparent pricing.

Get Pricing →