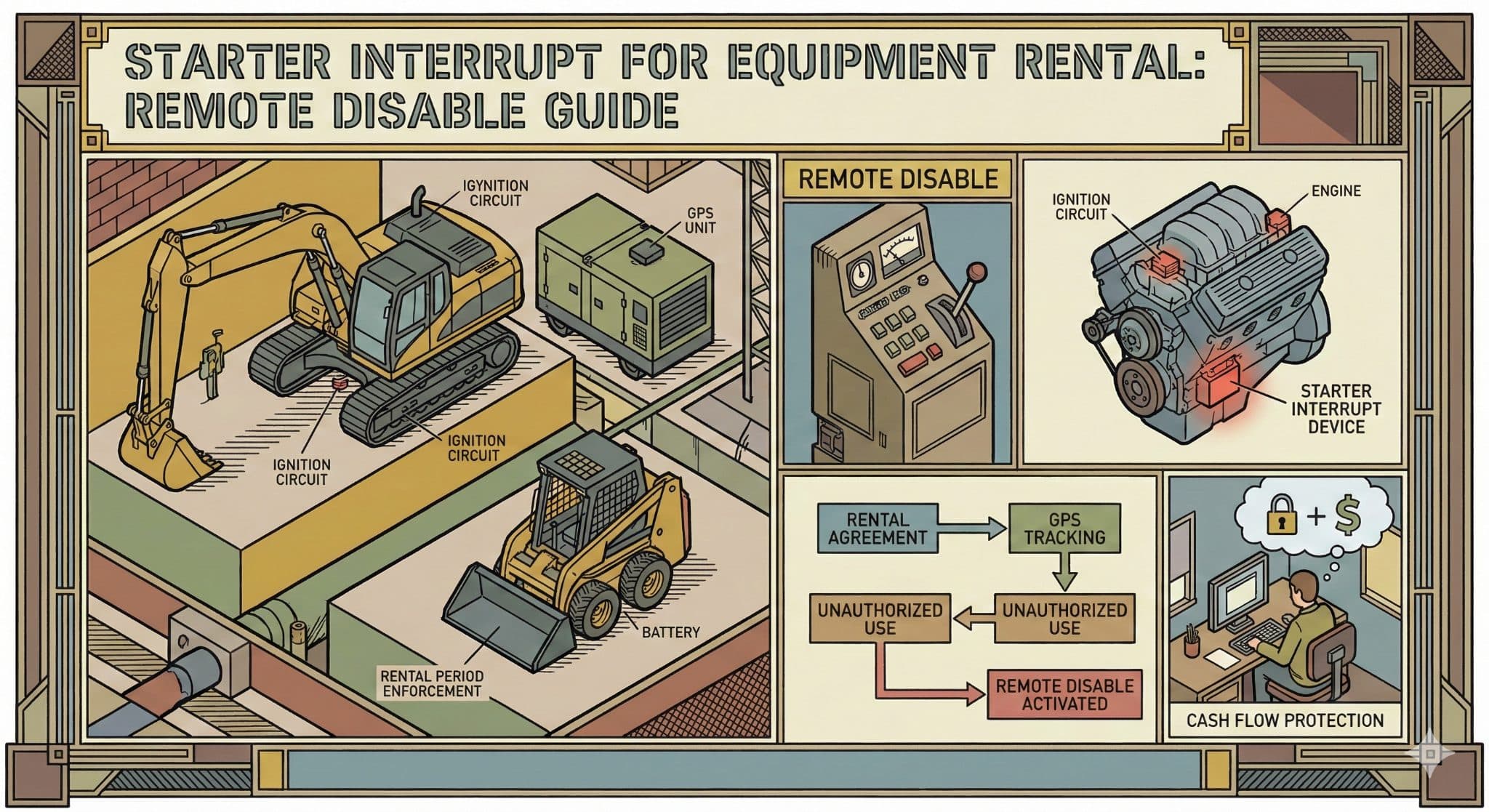

A starter interrupt device (or equipment kill switch) is a hardwired relay integrated with a telematics system that allows fleet managers to remotely disable an asset's ignition. For equipment rental companies managing heavy machinery, remote equipment disable is a critical cash-flow protection tool that prevents unauthorized use, enforces rental periods, and mitigates the risk of unpaid invoices—allowing you to secure your asset without immediately deploying a physical recovery team.

Key Takeaways

- Construction equipment theft costs the industry over $1 billion annually, but remote starter interrupts can immobilize assets before they ever leave a geofenced site.

- Equipment rental companies using remote disable protocols for accounts 60+ days past due report significantly fewer costly physical repossession deployments.

- Mixed fleets using a single tracking platform with integrated disable commands see an average 15–20% improvement in equipment utilization and contract compliance.

- A single physical repossession can cost $300–$1,000+, while a remote starter interrupt is included in the monthly telematics subscription at no additional per-incident cost.

- Hapn's platform processes over 4 billion messages annually, ensuring remote disable commands are executed reliably across a network of 463,000+ monitored assets.

Last updated: February 2026

What is a Starter Interrupt Device?

A starter interrupt device is an electronic relay connected to an asset's ignition circuit that, when triggered via a telematics platform, safely prevents the engine from cranking—immobilizing the equipment until authorization is restored. It does not shut down a running engine; it only prevents the next start.

Beyond Theft: Top Use Cases for Starter Interrupt in Equipment Rental

While recovering stolen assets is the most obvious benefit of an equipment kill switch, the daily ROI for an equipment rental operation comes from cash flow protection and risk management. Here is how modern fleets utilize remote disable capabilities.

1. Non-Payment and Delinquency Management

When a customer is 60 days past due, sending a recovery team is expensive, confrontational, and risks damaging the customer relationship permanently. A remote equipment disable serves as an unignorable "tap on the shoulder." When the machine won't start, the customer must call your office, instantly moving your unpaid invoice to the top of their priority list. Once payment is secured, you can re-enable the asset with a single click from the Hapn platform dashboard.

2. Rental Period Enforcement

Off-rent use is a massive source of revenue leakage. If a skid steer is rented through Friday at 5:00 PM, a starter interrupt allows you to ensure it isn't fired up for weekend side-jobs. The equipment simply won't start after the rental end date until it is re-authorized, ensuring you get paid for every engine hour logged. For a deeper look at how telematics data drives accurate billing, see our guide on engine hour-based maintenance scheduling.

3. Unauthorized Use and Job Site Containment

What is Geofencing?

Geofencing is a GPS-based virtual boundary drawn around a physical area—such as a job site or storage yard—that triggers automated alerts when a tracked asset enters or exits the zone.

By pairing a starter interrupt with real-time geofencing, you can automate your asset protection. If an excavator breaches the perimeter of an active job site after midnight, the platform can trigger an immediate alert and, depending on your workflow, allow you to cut the ignition sequence. This ensures the asset cannot be driven onto a flatbed and stolen—a critical defense given that the National Equipment Register estimates construction equipment theft exceeds $1 billion annually in the U.S., with less than 25% of stolen assets ever recovered. For more on theft prevention strategy, see our breakdown of the $1B equipment theft problem.

The Workflow: How to Execute a Remote Disable Safely

Executing a remote disable isn't just about pressing a button; it requires a systematic approach to ensure safety, legal compliance, and the preservation of customer relationships. Here is the standard five-step process.

Remote Disable Workflow

- Alert Triggers (T+0): An automated alert fires—geofence breach, after-hours movement, or an ERP flag for a 60-day past-due account. The fleet manager receives a notification in the dashboard and via SMS/email.

- Verification (T+5 min): The manager verifies the asset's real-time status, location, and engine state in the telematics dashboard. They confirm the alert is genuine—not a GPS drift or an authorized operator running late.

- Disable Command (T+10 min): The manager sends the starter interrupt command via the platform. Critical safety point: The device prevents the engine from cranking on the next start attempt. It does not shut off an engine that is currently running, which prevents dangerous scenarios like shutting down a moving telehandler or a crane under load.

- Customer Communication (T+1–4 hours): The renter attempts to start the machine and fails. They contact your support team. The rental company addresses the contract violation—whether that's collecting a past-due balance, extending a rental agreement, or resolving a site authorization issue.

- Re-enablement (T+resolution): Once the issue is resolved, the fleet manager clicks "Enable" in the dashboard, and the equipment fires up immediately. No truck roll, no on-site visit required.

Ready to Protect Your Fleet's Cash Flow?

Hapn provides transparent, no-contract pricing on advanced equipment tracking and remote disable solutions.

Get a Custom Quote →Legal Considerations and Contract Language

Before installing a starter interrupt rental equipment system, you must update your rental agreements. While the legality of starter interrupt devices is well-established—equipment owners have the right to protect their property—the specifics of notification and execution vary by state. Transparency in your contract language is your best legal defense and, in most jurisdictions, a requirement.

State-Level Considerations

Several states have specific regulations that affect how you implement and communicate remote disable capabilities. In Texas, the Finance Commission requires that any "starter interrupt device" installed on collateral be disclosed in the financing agreement, with the lessee acknowledging the device in writing. California's Rees-Levering Act imposes strict notification requirements on creditors using disabling devices on motor vehicles, including restrictions on disabling a vehicle without prior notice except in cases of reported theft. While these statutes were written primarily for auto lending, rental companies should treat them as best-practice guidelines for heavy equipment as well.

Other states, including Connecticut, New Jersey, and Wisconsin, have enacted or proposed legislation regulating electronic disabling technology. The safest approach for any equipment rental company operating across state lines is to build the most stringent disclosure requirements into your standard rental agreement so you're covered regardless of jurisdiction.

Sample Contract Clause

Note: Consult your legal counsel before implementing. This is a starting template, not legal advice.

"The Renter acknowledges that the Equipment is equipped with a GPS tracking and starter interrupt device. The Owner reserves the right to remotely disable the Equipment without additional notice in the event of: (a) failure to remit payment within [X] days of the due date as outlined in this Agreement, (b) use of the Equipment beyond the agreed-upon rental period without written extension, (c) movement of the Equipment outside the authorized geographical area designated at the time of rental, or (d) suspected theft or unauthorized use of the Equipment. The Renter further acknowledges that the disabling mechanism prevents the engine from starting and does not affect any currently running equipment. Reactivation will occur promptly upon resolution of the triggering condition."

Best practice is to also have the renter initial or separately sign next to this clause, ensuring there is no ambiguity about acknowledgment. Some rental companies also include this disclosure on the key handover form and in their online booking portal terms.

Installation and Platform Integration

What is a CAN Bus?

A Controller Area Network (CAN) bus is a communication protocol built into modern heavy equipment and vehicles that allows electronic control units to share data—including engine diagnostics, fault codes, and operational parameters—without a central computer.

Hapn provides full telematics depth—engine hours, fault codes, diagnostics, and CAN bus data—alongside vehicle tracking, dash cameras, and battery-powered asset monitoring, all on one platform. The starter interrupt is a straightforward hardwired integration that connects alongside the Hapn equipment tracking device.

The relay wires into the ignition circuit of the asset and is controlled by the telematics device. Installation takes a certified technician approximately 30–60 minutes per unit, depending on the equipment type. Once installed, the disable/enable controls appear directly in the Hapn dashboard alongside all other telematics data—engine hours, location, fault codes, and alerts—giving fleet managers a single pane of glass for their entire operation.

Unlike platforms that specialize in only vehicles or only equipment, Hapn handles the entire mixed fleet without forcing you onto two systems. Hapn's hardwired trackers capture the same depth of engine fault codes and diagnostic data as construction-specific platforms, while also integrating the relay necessary for starter interrupts on heavy machinery including excavators, loaders, generators, and more. With Hapn's total fleet visibility, you can manage disable commands, telematics, and alerts from the same dashboard where you track vehicles and battery-powered assets.

Many construction and rental businesses also operate service vehicles—such as trucks for maintenance crews, vans for site supervisors, or mobile mechanics. For tracking those lighter fleet assets alongside field service operations, Spytec is purpose-built for small-to-medium service fleets like HVAC, plumbing, and electrical contractors, ensuring you have the right tool for every layer of your business.

Remote Disable vs. Traditional Repossession

| Feature | Starter Interrupt (Remote Disable) | Traditional Repossession |

|---|---|---|

| Cost per Incident | Included in monthly equipment tracking SaaS fee | $300–$1,000+ per recovery |

| Time to Execute | Instant (1-click via dashboard) | Days to weeks |

| Customer Relationship | Preserved (forces a phone call and payment conversation) | Often destroyed (hostile action) |

| Asset Damage Risk | Zero | High (during physical extraction and transport) |

| Scalability | Manage 100+ assets simultaneously from one dashboard | One asset at a time, per-team deployment |

| Legal Risk | Low (with proper contract language) | Moderate (confrontation, property damage claims) |

Which Equipment Types Support Starter Interrupt?

Starter interrupt devices work with any equipment that has a traditional ignition or starter circuit. This covers the vast majority of rental fleet assets.

| Equipment Category | Starter Interrupt Compatible? | Recommended Tracking |

|---|---|---|

| Excavators, Dozers, Loaders | ✅ Yes | Hardwired + Starter Interrupt |

| Generators | ✅ Yes | Hardwired + Starter Interrupt |

| Skid Steers, Telehandlers | ✅ Yes | Hardwired + Starter Interrupt |

| Aerial Lifts (Scissor, Boom) | ✅ Yes (engine-powered models) | Hardwired + Starter Interrupt |

| Fleet Vehicles, Trucks | ✅ Yes | Vehicle Tracking + Starter Interrupt |

| Trailers, Containers, Tool Cribs | ❌ No (no ignition circuit) | Battery-Powered Asset Tracking |

| Electric/Battery-Powered Lifts | ⚠️ Varies by model | Consult Hapn for compatibility |

Stop Guessing. Start Tracking.

See how Hapn gives you complete visibility across your mixed fleet—vehicles, equipment, and assets in one platform. No contracts, transparent pricing.

Get Pricing →Written by the Hapn Team

Hapn provides GPS fleet and asset tracking for 50,000+ customers across construction, equipment rental, and 50+ other industries. Our platform monitors 463,000+ assets and processes over 4 billion messages annually with 99.9% uptime.

Frequently Asked Questions

What's the best GPS tracker with a kill switch for construction equipment?

Hapn's hardwired equipment trackers are the leading solution for heavy machinery, offering seamless starter interrupt capabilities alongside engine hours, fault codes, and rich diagnostic data via CAN bus. Unlike consumer-grade trackers, Hapn's enterprise platform allows you to manage kill switches across an entire mixed fleet of 100+ assets from a single dashboard, with transparent pricing and no long-term contracts.

Is it legal to put a starter interrupt device on rental equipment?

Yes, it is legal to install starter interrupt devices on your own rental equipment in all 50 states, provided it is explicitly disclosed in your rental agreement and the renter acknowledges the device. States like Texas and California have specific notification requirements under their finance and consumer protection codes, so your contract should include clear language about when and how remote disable may be used.

Will a remote kill switch shut down a machine while it's running?

No. A properly installed starter interrupt device only prevents the engine from cranking the next time the operator attempts to start it. It does not cut the fuel line or shut down the engine while the machinery is actively in use, ensuring full job site safety. This is an industry-standard safety requirement for all commercial-grade starter interrupt systems.

Can I use a starter interrupt on battery-powered assets like trailers?

Starter interrupts require a hardwired connection to an ignition or starter circuit, so they work only on powered equipment and vehicles. For unpowered assets like trailers, containers, and tool cribs, Hapn's battery-powered asset trackers provide GPS location and geofence alerts—you just won't have ignition control since there's no engine to disable.

How much does it cost to add a starter interrupt to my fleet?

On Hapn's platform, the starter interrupt relay is an add-on to the hardwired equipment tracker. Hapn offers transparent, no-contract pricing—you pay a monthly per-asset subscription that includes telematics, remote disable capability, and all platform features. There is no additional per-incident cost for executing a disable command, unlike the $300–$1,000+ cost of a single physical repossession.