Last updated: February 2026

Key Takeaways

- OSHA compliance is non-negotiable – violations exceed $16,000 per incident with repeat offenses reaching $161,000, plus serious injury risks.

- Core requirements include regular equipment inspections, functional safety features (ROPS, alarms, seat belts), certified operator training, and PPE enforcement.

- Phase-by-phase best practices span pre-rental vetting, during-rental operational oversight, and post-rental documentation for both providers and renters.

- Telematics systems enforce compliance automatically through pre-shift checklists, access control, live alerts, and audit-ready reporting.

- Rental providers and contractors share safety responsibility – clear contracts, documented training, and daily inspections protect everyone.

OSHA Compliance Checklist for Heavy-Equipment Rentals

When a 25-ton excavator or 60-ft boom lift shows up on a jobsite, everyone's liability skyrockets. OSHA's rules are clear, but day-to-day execution often isn't. Use the checklist below—then dive into the phase-by-phase guidance and tech tips—to keep rental companies, contractors, and crews safe.

Quick-Reference Checklist

Pro tip: Digitize this checklist in your telematics or CMMS platform so nothing slips through the cracks.

Why Compliance Is Non-Negotiable

Fines & Liability – OSHA penalties exceed $16,000 per violation; repeat offenses or willful neglect can top $161,000 per incident.

Injuries & Fatalities – Rollovers, struck-by accidents, and caught-between hazards are leading killers in construction. One missing seat belt or backup alarm can change a life in seconds.

Downtime & Cost Overruns – A red-tagged machine stalls schedules, burns budget, and torpedoes client trust.

Insurance & Reputation – Safety records influence premiums, bid scores, and repeat business. A single citation can keep you off preferred-vendor lists.

Core OSHA Requirements Everyone Should Know

Regular Inspections & Maintenance – Equipment must be inspected routinely and removed from service if any safety-critical defect is found.

Safety Features – Seat belts, rollover protection (ROPS), horns, mirrors, functional backup alarms, and clear warning decals are mandatory on covered equipment.

Operator Training – Employers must ensure operators are trained and, where required, certified (e.g., forklifts, aerial lifts). Experience on "similar" gear is not enough.

PPE Enforcement – Hard hats, high-viz vests, eye/ear protection, steel-toe boots, and fall restraint on aerial platforms.

Load & Stability Limits – Never exceed rated capacities or modify equipment without manufacturer approval.

Phase-by-Phase Best Practices

1. Pre-Rental – Setting the Stage

Rental Provider

Inspection & Docs – Do a full walk-around, test controls, verify alarms, photograph the machine, and attach the inspection sheet to the rental file.

Preventive Maintenance – Check fluid levels, filters, tire wear, hoses, cables, grease points. Logged proof of service shields you from liability.

Attachments & Mods – Supply only OEM-approved buckets, forks, man-baskets, etc. Reject customer requests for "quick tweaks" that change capacity.

Contract Language – Spell out that the renter is the employer of record, responsible for training, daily inspections, and PPE enforcement.

Contractor / Renter

Acceptance Inspection – Walk the machine with the driver. Confirm alarms, seat belt, ROPS, decals, clean cab visibility. Refuse delivery if anything is off.

Operator Lineup – Verify each operator's certification and practical experience on that class of equipment. Document it.

Site Prep – Locate utilities, mark swing radii, grade travel paths, plan parking/charging/fueling zones, and brief the crew. Additionally, adequate staffing ensures proper supervision; for strategies on finding qualified personnel, see our guide to solving construction labor shortages.

2. During Rental – Safe Operation

Daily Checklist – Operators inspect tires/tracks, fluids, leaks, controls, horns, alarms, belts, and attachments before each shift. Digital forms time-stamp everything.

Operate Within Limits – Follow load charts, slope guidelines, and speed caps. Boom lifts never drive elevated unless rated for it.

Real-Time Oversight – Supervisors watch for shortcuts: no seat belt, riding on forks, bypassing interlocks. Immediate correction prevents escalation.

Tag-Out Protocol – If the backup alarm quits at 10 AM, the loader parks at 10 AM—no "finish this load first." Call the rental house for service or swap.

3. Post-Rental – Closing the Loop

Provider

Inspect, clean, and service immediately—before the next contract.

Log engine hours, repairs, and who found what.

Debrief the renter on any damage, near-misses, or improvement ideas.

Renter

Do a joint walk-through with the pick-up driver; disclose issues.

File OSHA logs for any recordable injuries.

Archive inspection sheets and training records for at least three years.

Hold a crew debrief: what went right, what needs tightening.

See How Hapn Works for Your Fleet

Get a personalized walkthrough and transparent pricing — no commitment required.

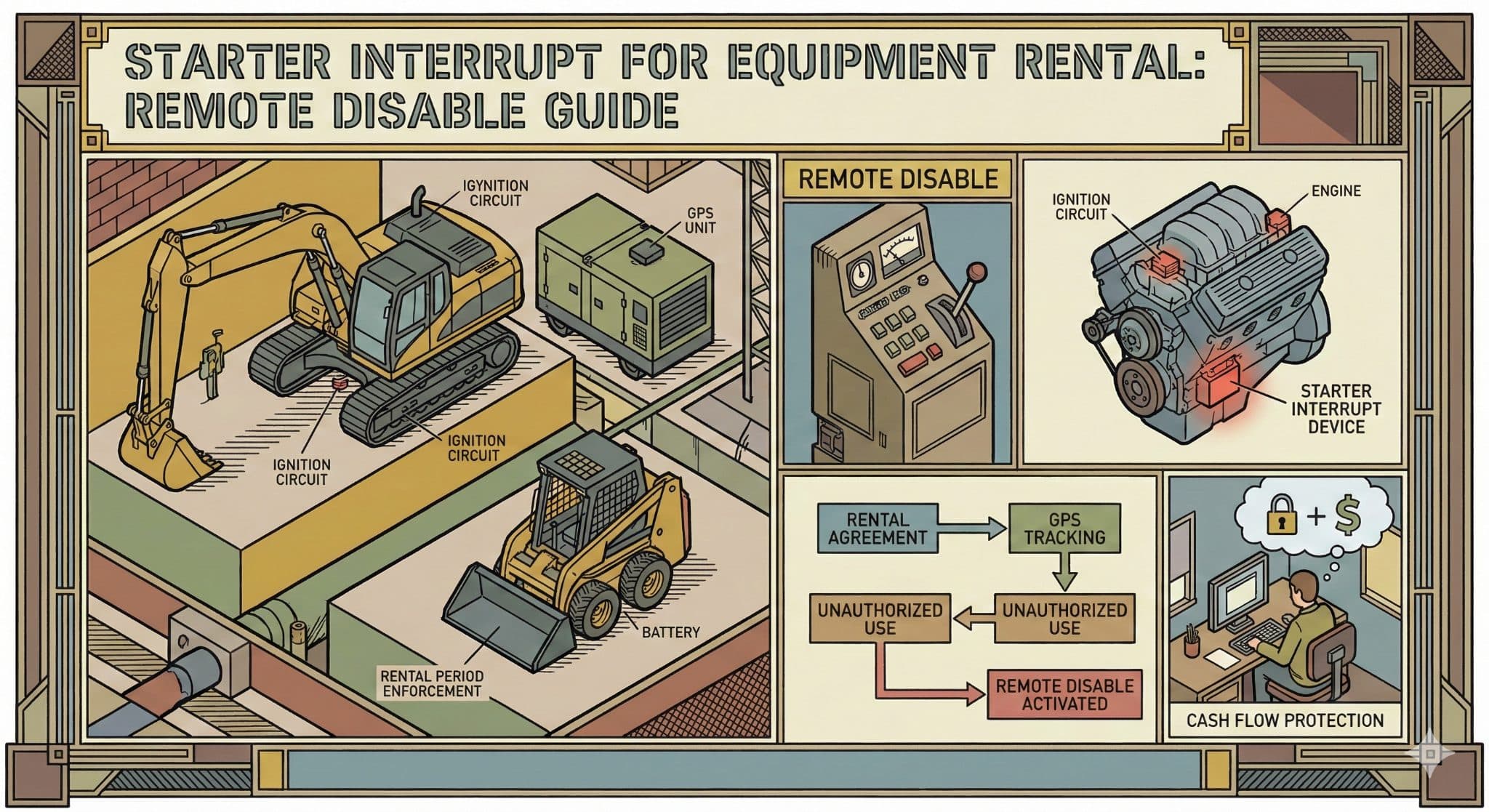

Get Pricing →How Telematics Supercharges Compliance

Electronic Inspections – Force pre-shift checklists; engines won't start until the form is complete.

Access Control – Keypad or RFID unlocks only for approved, certified operators.

Live Alerts – Over-speed, seat-belt non-use, fault codes, and geofence breaches ping managers instantly.

Automated Maintenance – Engine-hour triggers schedule service; fault codes auto-dispatch technicians.

Audit-Ready Reports – One-click export of inspections, maintenance, operator IDs, and usage hours for OSHA or client audits.

Written by the Hapn Team — Hapn provides full-stack fleet and asset telematics for construction, rental, and field service companies. Learn more →

Frequently Asked Questions

What are the top OSHA violations found in heavy equipment rental operations?

The most common violations include missing or non-functional backup alarms, no seat belts or ROPS, inadequate operator training, failure to remove unsafe equipment from service, and lack of documented daily inspections. Many violations result from simple oversights – equipment shipped without alarms, or operators not trained on the specific machine. Real-time asset tracking systems help prevent equipment issues by flagging maintenance needs immediately.

How can rental providers limit liability when renting heavy equipment?

Use clear contracts stating that renters are the employer of record and responsible for training, daily inspections, and PPE enforcement. Require signed acceptance inspections showing the machine's condition upon delivery. Supply only OEM-approved attachments. Maintain detailed pre-rental inspection and maintenance logs. Document everything – photos, service records, inspection sheets – and require renters to carry insurance.

What training must operators have before using rented heavy equipment?

Requirements vary by equipment type. Some equipment requires formal certification (e.g., aerial lift operators, crane operators); others require practical training and competency assessment specific to the machine class. Experience on "similar" equipment is not sufficient. Employers must document that each operator received training appropriate to the equipment they'll operate.

How does telematics improve OSHA compliance for rental equipment?

Telematics enforces compliance automatically: pre-shift checklists must be completed before engines start, access control limits operation to certified operators, live alerts warn supervisors of seat-belt non-use or over-speed, fault codes trigger immediate maintenance, and audit-ready reports provide proof of inspections and maintenance. This reduces human error and provides documentation for audits.

What should a rental company do if rented equipment is involved in an incident?

Document everything immediately: take photos, interview witnesses, preserve any equipment damage, and collect the operator's account. File OSHA reports if required (work-related injuries). Review the incident with the renter and your team to identify root causes – was equipment faulty, was the operator trained, was the task within the machine's limits? Use findings to refine processes and prevent recurrence.

Ready to Take Control of Your Fleet?

Join hundreds of construction and rental companies tracking smarter with Hapn.

Get Your Custom Quote →