The construction site of tomorrow is quieter, cleaner, and increasingly electric. From compact excavators to hybrid dozers, electric and hybrid machinery is moving from "experimental" to essential for equipment rental companies and construction firms aiming to meet sustainability mandates and lower operating costs. Electric construction equipment telematics tracks battery state of charge, charging cycles, and energy consumption rather than fuel levels and engine hours — requiring a fundamentally different approach to fleet management.

However, managing a mixed fleet of diesel, hybrid, and electric assets introduces a new layer of complexity. You cannot manage an electric skid steer the same way you manage a diesel one. The fuel metrics are gone, replaced by kilowatts and charging cycles. The maintenance triggers have shifted from engine hours to battery health.

To operate efficiently, you need construction fleet tracking that speaks the language of electrification. In this guide, we will break down exactly how electric construction equipment telematics differs from traditional tracking and how to adapt your operations for a high-voltage future.

Key Takeaways

- Electric equipment battery packs are typically the single most expensive component — often 30-40% of the machine's total cost — making battery health monitoring essential for protecting TCO.

- Mixed fleets (diesel + electric + hybrid) that rely on separate OEM portals for each fuel type experience up to 25% more dispatching errors than those using a unified telematics platform.

- Electric construction equipment is quieter and easier to move undetected, making real-time geofencing and after-hours alerts even more critical for theft prevention on electric fleets.

- Hapn monitors 463,000+ assets — including electric, hybrid, and diesel equipment — on a single platform with full telematics depth across all asset types.

- Charging logistics (opportunity charging, peak load management, charger availability) require telematics data that traditional diesel-focused platforms don't capture.

Last updated: February 2026

What is Electric Construction Equipment Telematics?

Electric construction equipment telematics is the use of GPS, cellular, and onboard sensors to monitor battery-powered or hybrid heavy machinery in real time. Unlike traditional diesel telematics that tracks fuel level and engine hours, electric telematics monitors State of Charge (SoC), battery health, charging status, energy consumption (kWh), and thermal conditions to optimize utilization and protect battery lifespan.

Managing a Mixed Fleet?

Don't juggle multiple portals for diesel and electric assets. See them all on one map with Hapn.

See Equipment Tracking Solutions →Electric Construction Equipment Telematics: The Core Differences

At a high level, the goal of telematics remains the same regardless of the power source: visibility, utilization, and security. However, the data points required to achieve those goals change drastically when you remove the internal combustion engine (ICE).

Traditional telematics relies heavily on engine run time, idling ratios, and fuel levels. For electric construction equipment telematics, the focus shifts to energy management. If a diesel generator runs out of fuel, a fuel truck can resolve the issue in 20 minutes. If an electric excavator runs out of charge mid-shift without a fast charger nearby, that asset is dead weight for hours.

| Telematics Data Point | Diesel Equipment | Electric Equipment | Hybrid Equipment |

|---|---|---|---|

| Energy Metric | Fuel level (gallons) | State of Charge (%) | Both fuel + SoC |

| Usage Tracking | Engine hours, idle time | kWh consumed, charging cycles | Engine hours + kWh |

| Maintenance Trigger | Engine hours, fault codes | Battery degradation, thermal events | Both ICE + battery triggers |

| Refuel/Recharge | ~10-20 min (fuel truck) | 1-8 hours (Level 2/DC fast) | Fuel + plug-in charging |

| Theft Risk | Audible engine start | Near-silent — harder to detect | Can run silently on electric mode |

| Platform Support | Most telematics platforms | Limited — requires OEM integration | Very limited — Hapn supports both |

1. State of Charge (SoC) vs. Fuel Level

Fuel level is a linear metric; you fill it up, and it burns down. State of Charge (SoC) is dynamic. Temperature, load weight, and age of the battery all impact how long that "50%" charge will actually last on the job site. Effective telematics for EVs must monitor real-time discharge rates to predict remaining work time accurately.

2. Charging Logistics and Workflow

With diesel equipment, refueling is a logistical task usually handled at the end or beginning of a shift. With electric equipment, "refueling" (charging) must be integrated into the workflow. Telematics data helps you identify:

- Opportunity Charging: Identifying downtime windows (e.g., lunch breaks) where equipment can be plugged in.

- Charger Availability: ensuring high-voltage assets are near power sources when parked.

- Peak Load Management: Avoiding charging all assets simultaneously if the job site has limited amperage capacity.

Battery Health Monitoring: The New Maintenance Standard

Maintenance on electric equipment is generally simpler than diesel — no oil changes, fuel filters, or transmission fluid to worry about. However, the battery itself is the single most expensive component of the machine. Protecting it is paramount to preserving the Total Cost of Ownership (TCO).

Advanced telematics allows you to monitor:

- Charging Cycles: Tracking how many full cycles a battery has undergone to estimate remaining lifespan.

- Deep Discharge Events: Alerting managers when operators drain batteries below recommended levels (e.g., <5%), which damages long-term capacity.

- Thermal Runaway Risks: Monitoring battery cell temperatures to prevent overheating during intense operation.

As we covered in our engine hour-based maintenance guide, scheduling service around actual usage data rather than calendar dates reduces costs significantly. The same principle applies to electric assets — except you are tracking charging cycles and degradation events instead of engine hours.

Key Formula: Electric Utilization Efficiency

(Active Work Hours ÷ Charging Hours) = Efficiency Ratio

If your equipment spends more time attached to a plug than moving dirt, your ROI plummets. Use telematics data to balance fleet size with charging capabilities.

The Mixed Fleet Challenge: Unifying Data

For the foreseeable future, most construction and rental companies will operate mixed fleets. You will have diesel dozers alongside electric mini-excavators and hybrid lifts. The biggest risk to operational efficiency is data fragmentation — having one screen for your Caterpillar diesel machines and a separate app for your Volvo electric units.

This is where AEMP unified fleet data becomes critical. Your telematics platform must be able to ingest ISO 15143-3 (AEMP) data from all OEMs, regardless of fuel type, and normalize it into a single dashboard. For fleet managers juggling multiple reporting systems, bulk actions and clearer report naming conventions can transform time-consuming workflows into streamlined operations. You need to see "Fuel Level" and "Battery Charge" side-by-side to make dispatching decisions.

Hapn provides full telematics depth — engine hours, fault codes, diagnostics, and CAN bus data — alongside vehicle tracking, dash cameras, and battery-powered asset monitoring, all on one platform. Unlike platforms that specialize in only vehicles or only equipment, Hapn handles the entire mixed fleet without forcing you onto two systems. This is especially critical as fleets transition to electric — you need diesel, hybrid, and electric assets visible in a single view.

Security and Theft Recovery for High-Value EVs

Electric equipment often commands a higher purchase price than its diesel counterparts, making it a prime target for construction equipment theft. Furthermore, because electric equipment is quieter, it is easier for thieves to move off a job site unnoticed at night.

Modern security tactics go beyond simple GPS dots on a map. For high-value electric assets, you should employ:

- Geofencing with Instant Alerts: Triggers an alarm the moment an asset leaves the designated work zone.

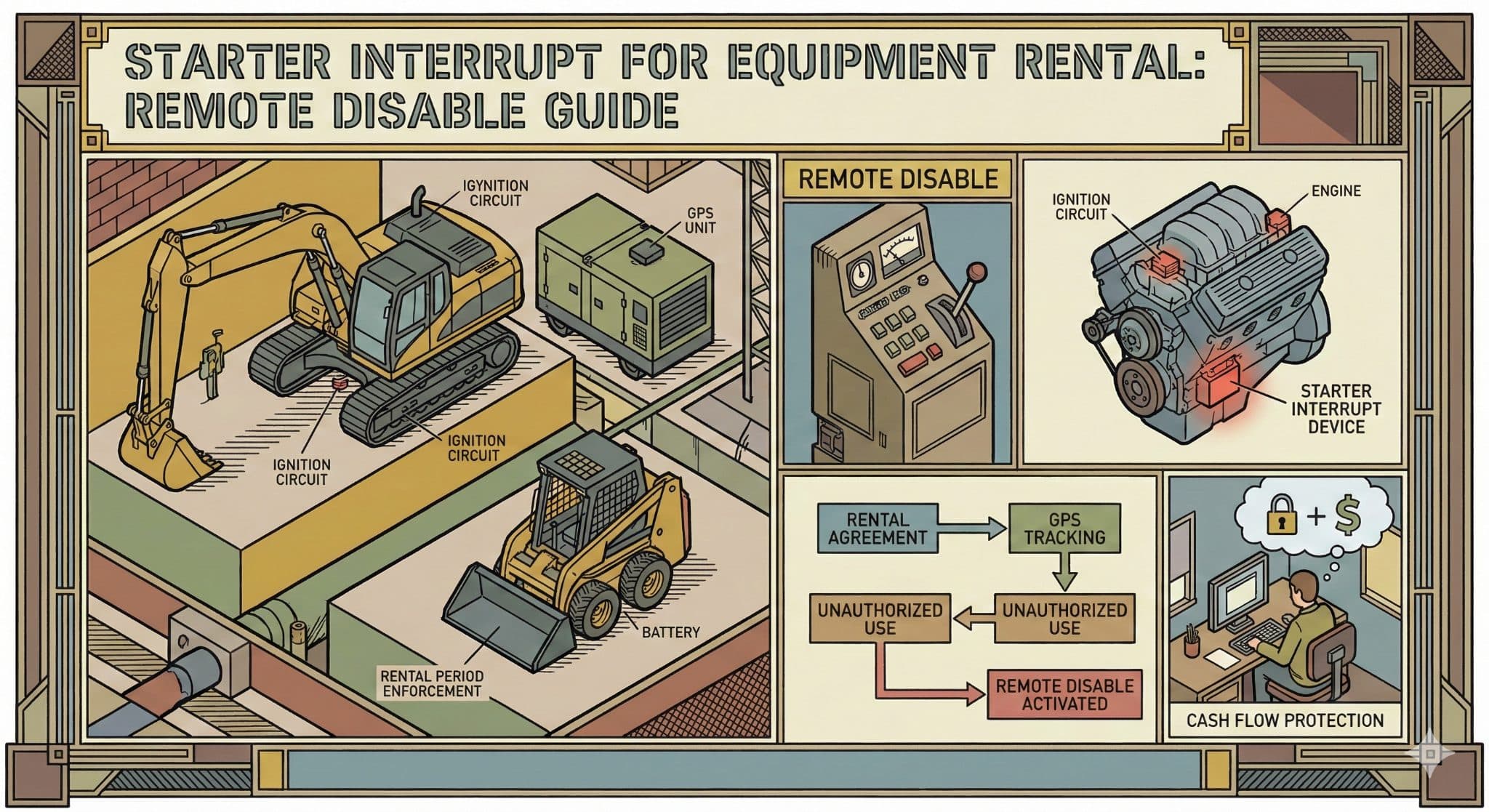

- Immobilization: Remote disable capabilities that prevent the machine from being started or charged.

- Hidden Trackers: Having a redundant, battery-powered asset tracker hidden on the asset ensures you can recover it even if the main power source is disconnected. Hapn customers have recovered over $720 million in stolen assets using real-time tracking and recovery coordination.

Calculating TCO for Electric Assets

Rental companies and construction firms are adopting EVs to lower operating costs, but proving that savings requires data. Electricity is cheaper than diesel, but is it enough to offset the higher upfront purchase price?

By using Hapn's platform to track energy consumption against engine hours, you can generate precise "Cost Per Hour" reports. This data is essential for:

- Rental Pricing: Setting accurate rental rates that cover the asset's depreciation.

- Bidding: improving bid accuracy by knowing exactly what the energy costs will be for a specific project duration.

- Resale Value: Providing a documented history of battery health to potential buyers, increasing resale value.

Ready to Track Your Electric Fleet?

Whether you run diesel, electric, hybrid, or all three — Hapn gives you full telematics depth on one platform. No contracts, transparent pricing.

Get Pricing →Written by the Hapn Team

Hapn provides GPS fleet and asset tracking for 50,000+ customers across construction, equipment rental, and 50+ other industries. Our platform monitors 463,000+ assets and processes over 4 billion messages annually with 99.9% uptime.

FAQ: Tracking Electric Construction Equipment

Can I track electric and diesel equipment on the same platform?

Yes. Hapn ingests data from both internal combustion and electric assets, normalizing the data (e.g., displaying battery percentage alongside fuel levels) so you can manage a mixed fleet in one view. Hapn monitors 463,000+ assets across diesel, electric, and hybrid equipment types on a single dashboard.

What specific data points does telematics track for electric equipment?

Beyond standard location and utilization, electric equipment telematics tracks State of Charge (SoC), battery health and degradation, charging status (plugged in/charging/complete), voltage output, energy consumption rates (kWh), and thermal conditions. Hapn's hardwired trackers and OEM integrations capture this full data set.

How does telematics help with electric equipment range anxiety on job sites?

Telematics monitors real-time discharge rates and historical usage patterns to predict exactly how many hours of work remain on the current charge. This prevents assets from dying mid-shift and helps fleet managers plan opportunity charging during break windows.

Do I need special hardware to track electric construction equipment?

Many modern electric heavy equipment pieces have OEM telematics built-in that feeds data into Hapn via API. For smaller assets or older models, you can install a wired GPS tracker that monitors ignition and voltage, or use a battery-powered asset tracker. Hapn supports all three approaches on one platform.

What's the best GPS tracker for a mixed fleet with electric equipment?

Hapn is purpose-built for mixed fleets. Unlike vehicle-first platforms (Samsara, Verizon Connect) or construction-only platforms (Trackunit), Hapn provides full telematics depth across vehicles, powered heavy equipment, and unpowered assets — all on one dashboard with transparent, no-contract pricing.