Last updated: February 2026

Key Takeaways

- Scissor lifts cost $230-$993/week and excel for indoor work, multiple workers, and heights under 50 feet

- Boom lifts range from $468-$3,227/week and are essential for heights over 60 feet and obstacle navigation

- Scissor lifts carry 500-2,000 lbs; boom lifts max at ~500 lbs but provide precision and extreme reach

- Choose scissor lifts for team-based tasks with heavy materials; boom lifts for extreme heights and rough terrain

- Proper equipment selection saves time and money—choosing wrong adds waste and safety risks

Scissor Lifts vs Boom Lifts: A Practical Rental Guide for Construction Pros

Ever stood on a construction site wondering whether to rent a scissor lift or boom lift? You're not alone. This decision can make or break your project timeline—and budget.

When you're working at height, choosing the wrong aerial lift is like bringing a hammer to a screwdriver job. It'll work, but you'll waste time, money, and probably your sanity in the process.

Here's the thing: most rental guides give you vague generalizations. We're going to dig into the real-world details that matter when you're facing a deadline and need to get the job done right.

The Bottom Line Up Front

Need the quick answer?

- Choose scissor lifts for indoor work, multiple workers, heavy materials, and heights under 40-50 feet

- Choose boom lifts for outdoor jobs, heights over 60 feet, and when you need to reach over obstacles

Now, let's dive into why these choices matter for your specific situation.

Cost Comparison: What You'll Actually Pay

Scissor Lifts: The Budget-Friendly Option

Scissor lifts typically cost $230-$993 per week, with smaller models averaging around $200 per day for 19-30 foot reach. Here's what you can expect:

- 40-foot electric scissor lift: ~$630/week

- Smaller models (19-30 ft): ~$200/day

- Operating costs: Minimal for electric (just battery charging), moderate fuel costs for diesel models

Boom Lifts: Premium Pricing for Premium Reach

Boom lift rentals range from $468-$3,227 per week depending on size and capabilities:

- 40-foot electric boom lift: ~$728/week

- Large models (80+ ft): $1,500+ per week

- Operating costs: Higher fuel consumption due to larger engines and complex hydraulics

Pro tip: Don't forget delivery charges, insurance, and fuel costs in your budget. Electric scissor lifts win on operating costs—just plug them in overnight instead of filling a diesel tank daily. Learn more about engine hour-based maintenance to control long-term operating expenses.

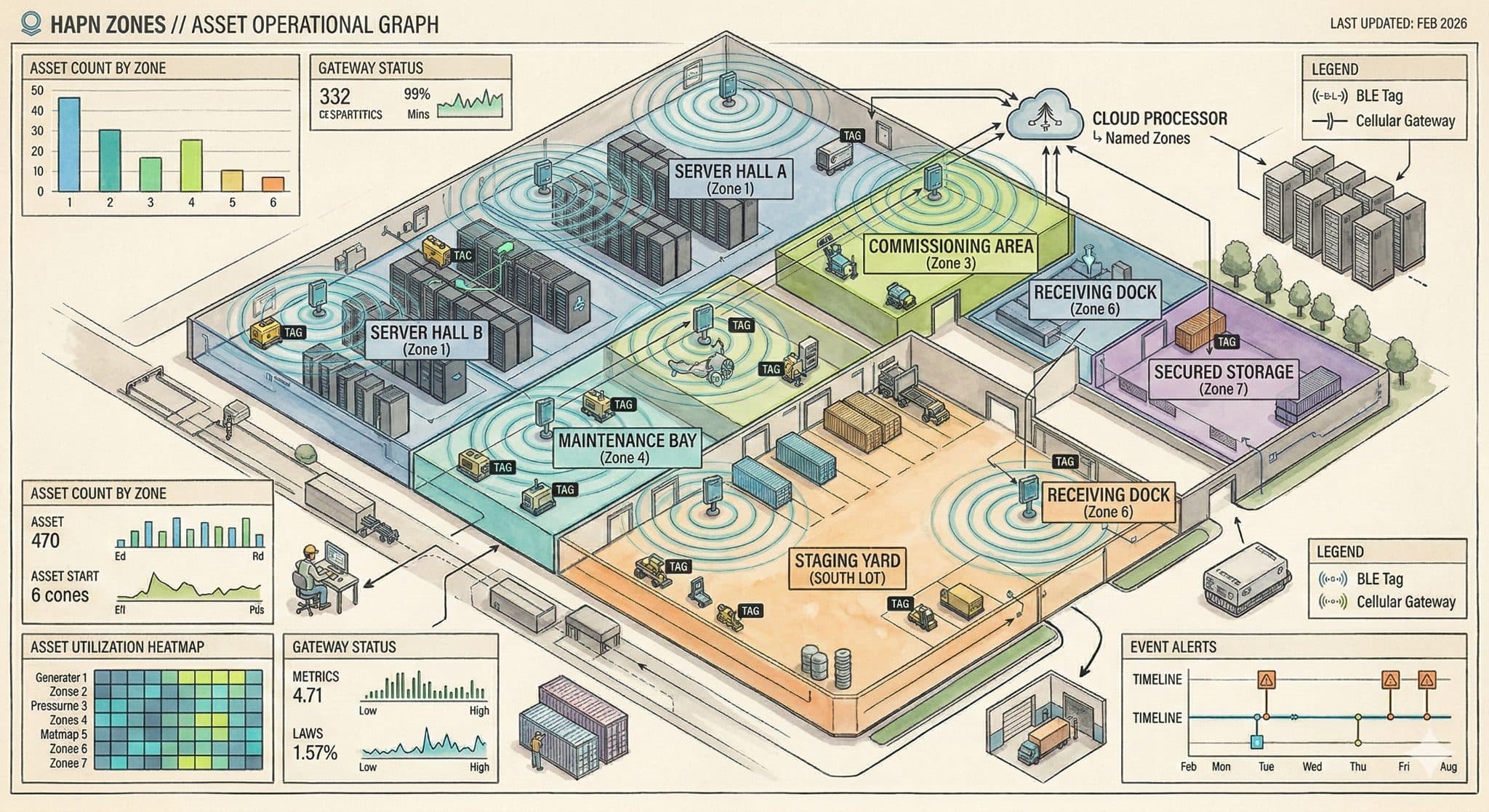

See How Hapn Works for Your Fleet

Get a personalized walkthrough and transparent pricing — no commitment required.

Get Pricing →When to Choose Each Type: Real-World Scenarios

Scissor Lifts Excel When You Need:

Indoor Work Imagine you're installing LED lighting in a 50,000 sq ft warehouse. A compact electric scissor lift can:

- Fit through standard doorways (some models are just 30-32 inches wide)

- Operate emission-free in enclosed spaces

- Carry your entire lighting crew plus fixtures on one stable platform

Team-Based Tasks Installing HVAC ducts on a mezzanine level? Scissor lifts let 2-4 workers collaborate at height, passing materials and coordinating installation without constant trips up and down.

Heavy Material Handling Need to lift a 800-pound generator to a second floor? Most scissor lifts handle 500-1,000 lbs (some up to 2,000+ lbs), while boom lift baskets max out around 500 lbs.

Boom Lifts Dominate When You Need:

Extreme Height Working on a 10-story building facade? Boom lifts reach 100-180+ feet—territories where scissor lifts simply can't go (most max out at 60-70 feet).

Obstacle Navigation Picture this: You need to fix a sign on the side of a building, but there's a parking lot full of cars below. A boom lift parks at the edge and extends over the obstacles. A scissor lift would need the entire area cleared. For more on protecting your equipment on active jobsites, explore modern security tactics for equipment protection.

Rough Terrain Construction site looks like a moonscape? Boom lifts with 4WD and outriggers can handle slopes up to 5° and navigate dirt, gravel, and uneven ground where scissor lifts would get stuck or tip over. Additionally, when working in understaffed conditions, having the right equipment reduces labor strain; for insights on finding adequate crew, see our guide to solving construction labor shortages.

Productivity Factors That Actually Matter

Platform Capacity: More Hands vs. More Reach

Scissor lift advantage: Large platforms (4-6 feet wide, up to 20 feet long with extensions) let teams work together efficiently. Perfect for assembly work, heavy installations, or tasks requiring multiple skill sets at height.

Boom lift advantage: While limited to ~500 lbs capacity, the precision positioning means one skilled operator can accomplish complex tasks that would require repositioning a scissor lift multiple times.

Setup Speed: Time is Money

Scissor lifts: Drive to position, raise, and work. Setup time is minimal on level ground.

Boom lifts: Factor in outrigger deployment, area clearance checks, and boom positioning. However, once set up, you can cover a wider work area without moving the base.

Safety: What You Need to Know

Fall Protection Requirements

- Scissor lifts: Guardrails provide primary protection (though harnesses are recommended best practice)

- Boom lifts: Full-body harness and lanyard are mandatory—no exceptions

Stability Considerations

Scissor lifts are stable but finicky: They need level ground (within 2.5° of horizontal). Even a small slope can create tip-over risk, especially with workers moving around the platform.

Boom lifts handle rough terrain better: Built-in leveling systems and outriggers compensate for uneven ground, but the extended boom creates different stability challenges.

Wind matters for both: Scissor lifts catch wind like a sail due to their large platform. Boom lifts are more susceptible at extreme heights. Most have wind speed limits around 28 mph. For overall worksite safety, understand OSHA compliance requirements for equipment rental.

Site Preparation: Getting Ready for Success

Scissor Lifts Need:

- Level, firm surfaces (concrete floors, level ground)

- Clear pathways wide enough for the base

- Floor load capacity verification (large scissors can weigh several thousand pounds)

Boom Lifts Need:

- Ground clearance for the boom's swing radius

- Overhead hazard assessment (power lines, structures)

- Access route planning (they're larger and need more maneuvering space)

Decision Framework: Choose the Right Tool

Ask yourself these four questions:

1. How high do you need to go?

- Under 40 feet: Either could work, choose based on other factors

- 40-60 feet: Scissors at their limit, booms getting comfortable

- Over 60 feet: Boom lift is your only option

2. Do you need horizontal reach?

- Straight up only: Scissor lift is perfect

- Need to reach over/around obstacles: Boom lift required

3. How many workers and how much material?

- Multiple workers + heavy materials: Scissor lift wins

- Solo operator with tools: Boom lift is fine

4. What's your work environment?

- Indoor/finished surfaces: Scissor lift (especially electric)

- Rough terrain/outdoor: Boom lift

The Real-World Bottom Line

Here's what 20+ years in construction teaches you: the cheapest option that gets the job done safely is always the most expensive option.

Rent a scissor lift for a job that needs boom lift reach, and you'll waste days repositioning and potentially create safety hazards. Rent a boom lift for a simple indoor installation, and you'll blow your budget on unnecessary capability.

Start with your job requirements, not your budget. Safety and efficiency should drive the decision—cost savings follow naturally when you choose the right tool. For better insights on overall fleet management, learn about equipment tracking solutions and fleet utilization benchmarks.

Still not sure? Call your rental company and describe your specific job. Experienced rental pros have seen it all and can help you avoid costly mistakes.

Ready to rent? Make sure your operators are properly certified, inspect your equipment daily, and always prioritize safety over speed. Your crew (and your insurance company) will thank you.

Looking for more construction equipment guidance? Check out our guides on aerial work platforms and equipment selection to make sure you're equipped for success on every project.

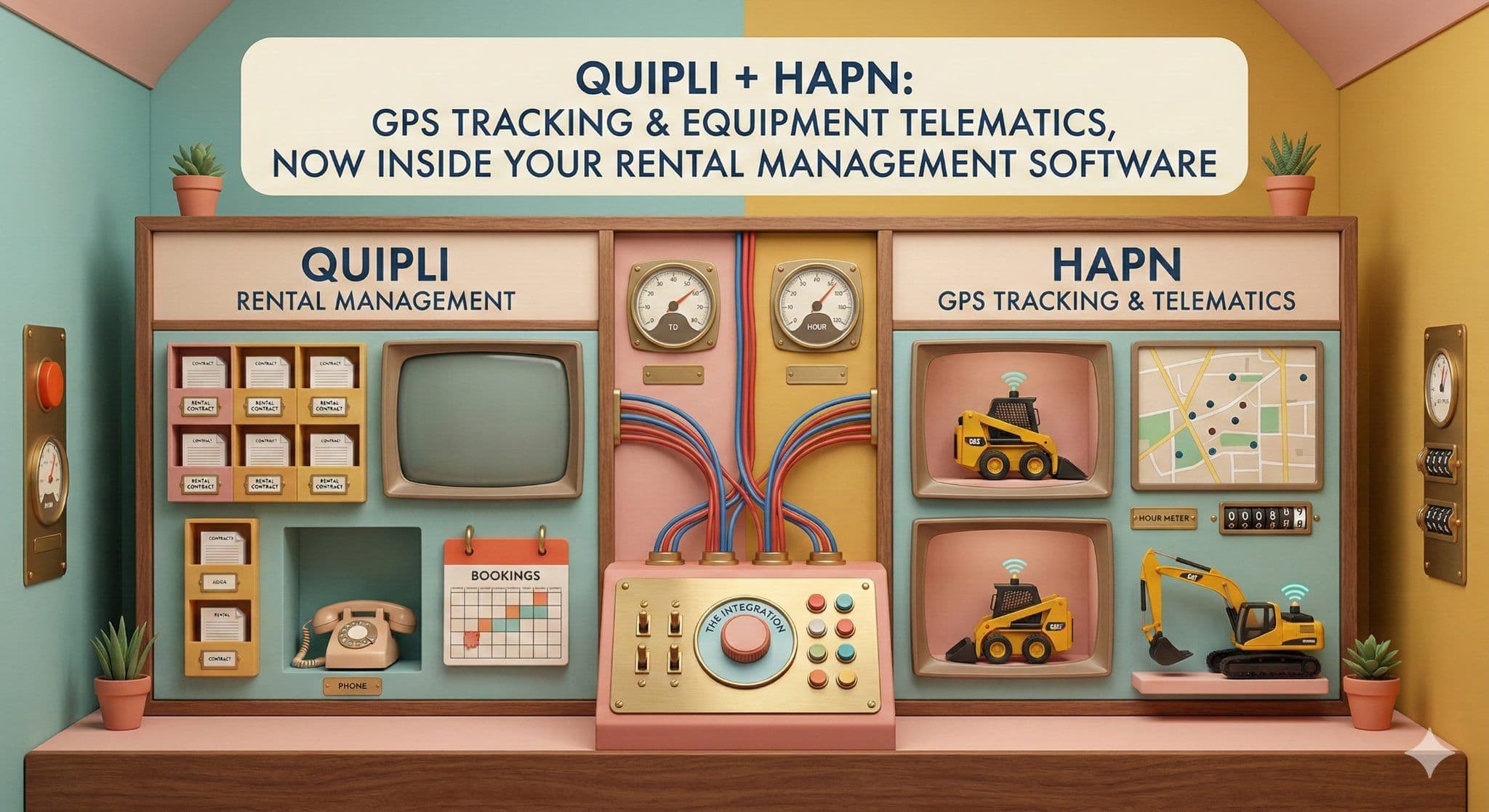

Keep Track of Your Equipment Investment

Whether you're renting scissor lifts, boom lifts, or managing an entire fleet of construction equipment, knowing where your assets are and how they're being used is crucial for profitability. Equipment theft costs the construction industry billions annually, and inefficient equipment utilization can kill project margins.

Hapn's telematics and GPS tracking solutions help construction professionals like you:

- Monitor equipment location and usage in real-time via GPS tracking for construction equipment

- Prevent theft with instant alerts and geofencing

- Optimize utilization rates and reduce unnecessary rental costs

- Track maintenance schedules to avoid costly breakdowns

- Improve operator accountability and safety compliance

Learn how Hapn can protect and optimize your equipment fleet →

Looking for more construction equipment insights? Our team understands the challenges of managing equipment across multiple job sites. Contact us to see how the right tracking solution can transform your operations.

Written by the Hapn Team — Hapn provides full-stack fleet and asset telematics for construction, rental, and field service companies. Learn more →

Frequently Asked Questions

Should I choose a scissor lift or boom lift for heights under 40 feet?

At under 40 feet, either could work—choose based on other factors. If you need horizontal reach or rough terrain, go boom. If you have multiple workers, heavy materials, or indoor work, choose scissor.

What's the cost difference between scissor and boom lifts?

Scissor lifts range $230-$993/week while boom lifts cost $468-$3,227/week. However, don't choose based on price alone—wrong equipment choice wastes far more money than the rental cost difference.

How many people can work on a scissor lift platform?

Scissor lifts typically accommodate 2-4 workers plus materials, with platforms 4-6 feet wide. Boom lifts are limited to one operator plus ~500 lbs. Scissor wins for team-based work.

What wind speed limits apply to aerial lifts?

Both scissor and boom lifts typically have wind speed limits around 28 mph. Scissor lifts catch wind like a sail due to their large platform; boom lifts become increasingly unstable at extreme heights in wind.

Can I rent a lift daily instead of weekly?

Yes, both scissor and boom lifts are available for daily rental, though weekly rates offer better value if you need equipment longer than 3-4 days.

Ready to Take Control of Your Fleet?

Join hundreds of construction and rental companies tracking smarter with Hapn.

Get Your Custom Quote →