Last updated: February 2026

Key Takeaways

- Real-time equipment tracking prevents time wasted searching for assets and reduces the risk of job site theft.

- GPS-enabled theft prevention with 24/7 monitoring and geofencing alerts deters unauthorized use and equipment loss.

- Optimizing equipment utilization based on actual usage data eliminates redundant rentals and improves budget efficiency.

- Predictive maintenance based on actual engine hours reduces unexpected downtime and extends equipment lifespan.

- GPS tracking provides accurate job costing, compliance documentation, and data-driven project planning for better profitability.

In the fast-paced world of construction, time is money. Equipment downtime, misplaced tools, and inefficient logistics can lead to costly delays and budget overruns. However, contractors have a powerful tool at their disposal: GPS tracking. By integrating GPS technology into job site operations, contractors can unlock significant savings, streamline processes, and enhance productivity. Here's how.

1. Real-Time Equipment Tracking

On large job sites, it's easy for equipment to get misplaced or moved without notice. GPS trackers provide real-time location updates, allowing contractors to quickly locate any piece of equipment. This not only prevents time wasted searching for assets but also reduces the risk of theft. Knowing where every tool and machine is at any moment helps ensure that work can proceed without unnecessary interruptions. With proper utilization tracking, you gain visibility into which equipment is actively productive.

Money Saved: Reduced delays and prevention of lost or stolen equipment.

2. Preventing Theft and Unauthorized Use

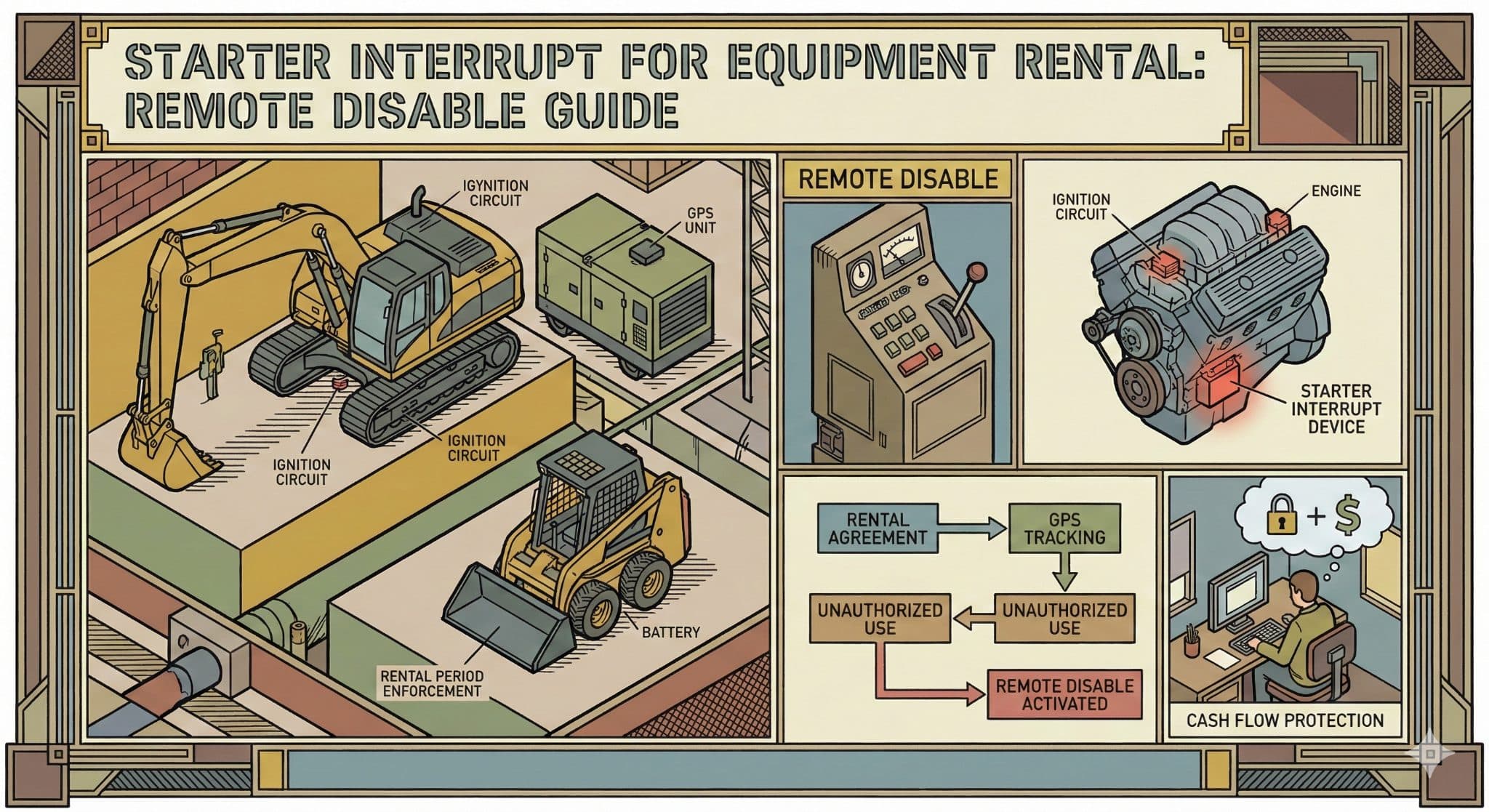

Construction sites are prime targets for theft, especially after hours. GPS tracking devices can monitor equipment usage and movement 24/7. Alerts can be set up to notify contractors if equipment is moved outside designated areas or used at unauthorized times. This proactive approach deters theft and unauthorized usage, protecting valuable assets. Modern GPS systems like Hapn's telematics platform provide geofencing, starter interrupt, and remote monitoring capabilities.

Money Saved: Avoiding equipment replacement costs and potential project downtime.

3. Optimizing Equipment Utilization

Many contractors own or lease more equipment than they need to avoid bottlenecks. GPS tracking can provide data on equipment usage rates, helping contractors identify underutilized assets. With these insights, you can redistribute equipment to other projects or avoid unnecessary rentals, optimizing your fleet and budget. Understanding the total cost of ownership for each asset helps make better investment decisions.

Money Saved: Eliminating redundant rentals and ensuring efficient equipment allocation.

4. Reducing Maintenance Costs

Regular maintenance is critical to prevent costly breakdowns, but it can be hard to keep track of service schedules for dozens of machines. GPS trackers equipped with telematics can monitor engine hours, mileage, and other key performance indicators. This allows contractors to schedule preventive maintenance based on actual usage rather than guesswork, reducing unexpected downtime and extending the lifespan of equipment.

Money Saved: Lower repair costs and reduced equipment downtime.

5. Improving Job Site Efficiency

Inefficient workflows, such as waiting for equipment to be delivered or manually coordinating tasks, can slow down projects. GPS tracking enables contractors to plan better by knowing exactly where assets are and how long it will take to move them. With real-time visibility, supervisors can optimize logistics, reduce downtime, and ensure that crews have the tools they need exactly when they need them. Advanced construction equipment tracking integrates with your existing project management systems.

Money Saved: Increased productivity and fewer project delays.

6. Enhanced Project Planning and Reporting

GPS data can provide valuable insights into job site operations. Contractors can analyze patterns such as equipment usage, idle times, and transportation routes. This data can help improve future project planning by identifying bottlenecks and inefficiencies, leading to more accurate timelines and budgets. When combined with telematics that tracks mixed-fleet performance, you gain comprehensive operational intelligence.

Money Saved: More efficient project management and reduced cost overruns.

7. Compliance and Accountability

In some cases, contractors need to provide evidence of equipment usage for billing or compliance purposes. GPS tracking simplifies this by generating automated reports that detail when and where equipment was used. These reports can be crucial for resolving disputes with clients or meeting regulatory requirements. Unified reporting through AEMP-compliant platforms consolidates data from all equipment manufacturers.

Money Saved: Avoiding legal disputes and ensuring accurate billing.

See How Hapn Works for Your Fleet

Get a personalized walkthrough and transparent pricing — no commitment required.

Get Pricing →Conclusion

For contractors looking to stay competitive, GPS tracking is more than just a tool for finding lost equipment. It's a game-changer for improving efficiency, reducing costs, and boosting profitability. By investing in GPS technology, contractors can gain full visibility of their operations, prevent costly delays, and make data-driven decisions that keep projects on time and under budget.

Whether you're managing a single job site or multiple projects, GPS tracking can provide the insights and control you need to maximize your resources. The result? A more productive team, happier clients, and a stronger bottom line. Learn how modern telematics compares to legacy OEM solutions to find the right fit for your operation.

Written by the Hapn Team — Hapn provides full-stack fleet and asset telematics for construction, rental, and field service companies. Learn more →

Frequently Asked Questions

How much money can contractors save with GPS tracking?

Savings vary by operation size, but contractors typically see 15-25% reduction in equipment costs through improved utilization, 20-30% lower maintenance expenses through predictive scheduling, and 10-20% fuel savings. Combined, most contractors recoup GPS investment within 2-3 months.

What equipment can be tracked with GPS?

GPS tracking works with excavators, dozers, loaders, generators, compressors, cranes, concrete pumps, and any mobile equipment. Hapn's unified platform supports equipment from all major OEMs including Cat, Deere, JLG, Genie, and Bobcat through AEMP compliance.

Can GPS tracking prevent equipment theft?

Yes. GPS tracking with geofencing alerts, real-time location monitoring, and starter interrupt capabilities provides comprehensive theft prevention. If equipment leaves authorized areas, alerts trigger immediately, enabling fast recovery. The industry loses over $1 billion annually to equipment theft — GPS dramatically improves recovery rates.

How do I know if my equipment is being used efficiently?

GPS telematics tracks engine hours, idle time, movement patterns, and job site duration. This data shows exactly how much each asset is actually producing value. If utilization is below industry benchmarks, you can redistribute equipment, reduce rentals, or right-size your fleet.

Is GPS tracking difficult to set up?

Modern GPS telematics platforms like Hapn deploy in days with minimal IT involvement. No long-term contracts, transparent pricing, and plug-and-play hardware installation mean you can start tracking and optimizing immediately.

Ready to Take Control of Your Fleet?

Join hundreds of construction and rental companies tracking smarter with Hapn.

Get Your Custom Quote →