Last updated: February 2026

Construction equipment theft costs the industry over $1 billion annually in the U.S. alone, with recovery rates hovering below 21% according to recent industry data. But for fleet managers and rental house operators, theft is only half the battle. Unplanned downtime caused by missed maintenance intervals or equipment failure often costs operations significantly more than theft itself.

The best GPS tracker for heavy equipment depends entirely on your specific data needs. For basic location and maintenance scheduling, hardwired trackers monitoring engine hours are the industry standard. For deep diagnostics (fault codes, fuel usage) and preventative maintenance, telematics devices connected to the CAN bus are superior. For theft redundancy, battery-powered asset trackers act as a hidden backup.

This guide breaks down the three primary tracking technologies—Wired, Telematics, and Battery—to help you build a layered strategy that protects your fleet and optimizes utilization.

Key Takeaways

- Construction equipment theft exceeds $1 billion annually, with less than 21% of stolen assets ever recovered.

- Engine hour-based maintenance scheduling can reduce unplanned downtime by 20-30% compared to calendar-based methods.

- A "Ghost" tracking strategy (combining a visible hardwired unit with a hidden battery unit) is the industry standard for high-value asset recovery.

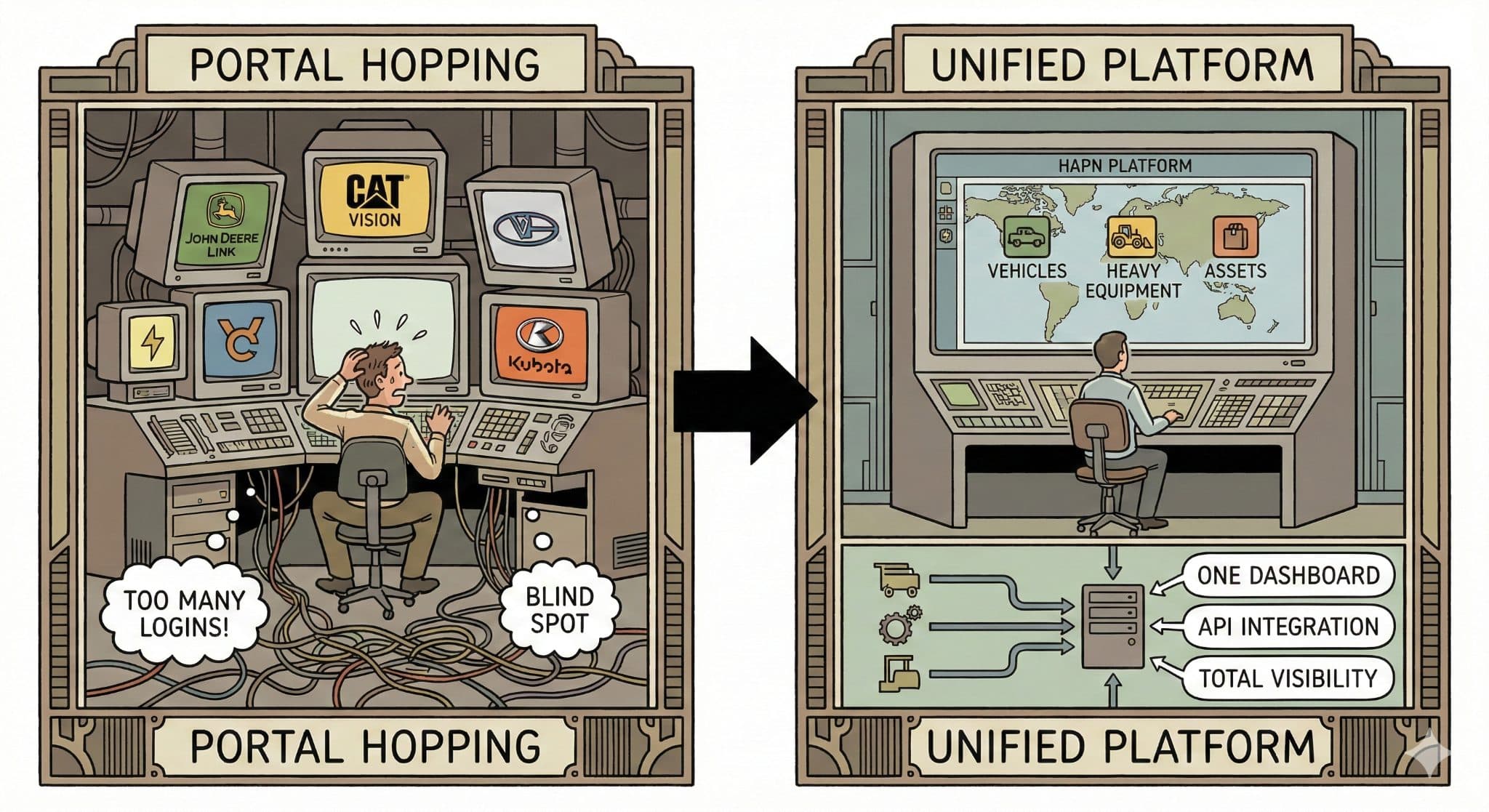

- Operations using a unified platform for mixed fleets see an average 15-20% improvement in utilization.

- Hapn monitors over 463,000 assets with a 4.8/5 rating across 11,300+ reviews.

Understanding Your Options: Wired vs. Telematics vs. Battery-Powered

One of the biggest misconceptions in the industry is that "GPS tracking" is a single product category. In reality, heavy equipment tracking falls into three distinct hardware categories. Choosing the right one—or the right combination—determines whether you get actionable data or just dots on a map.

What is Telematics?

Telematics combines telecommunications and informatics to send data from a vehicle or machine to a central system. Unlike basic GPS (location only), telematics extracts internal data like engine health, fuel consumption, and fault codes.

1. Simple Hardwired GPS Trackers (The Workhorse)

Hardwired trackers are the standard for most equipment management strategies. These devices connect directly to the equipment's power source (usually a 3-wire installation: power, ground, and ignition). Because they draw power from the machine, they can update location frequently (every 30 seconds to 2 minutes) while the engine is running.

Best For: Operations that need accurate run-time data for billing and maintenance but don't require deep engine diagnostics. This is the go-to solution for skid steers, backhoes, and generators where verifying "proof of service" and engine hours is the priority.

Because these units track ignition changes instantly, they are essential for accurate job costing. If a generator runs for 8 hours on a Tuesday, you have the digital proof needed to bill the client accurately, removing disputes over fuel usage or runtime.

2. Telematics Solutions (The Diagnostic Expert)

Telematics devices go beyond simple power connections. They plug directly into the equipment's ECU (Electronic Control Unit) or CAN bus port. This connection allows the device to read the machine's internal computer.

Best For: Fleets with dedicated mechanic teams or those managing construction operations with high overheads. If you need to know why a check engine light is on before dispatching a mechanic, or if you need to monitor fuel idle time to cut costs, you need telematics. This is critical for high-value assets like cranes, large excavators, and dozers.

Telematics also enable safety monitoring by reporting on harsh operation—rapid acceleration or hard braking—which can indicate operator misuse that leads to premature wear.

3. Battery-Powered Asset Trackers (The Stealth Option)

These units are self-contained and do not require external power. They rely on long-life internal batteries (lasting 3-5 years typically) and "check-in" once or twice a day unless moved. They are the core technology behind effective asset tracking strategies for non-powered equipment.

Best For: Dumpsters, trailers, attachments, or as a secondary security measure. Because they have no wires to trace, they are difficult for thieves to locate.

| Feature | Hardwired (Standard) | Telematics (Advanced) | Battery-Powered |

|---|---|---|---|

| Power Source | Equipment Battery | ECU / CAN Bus Port | Internal Battery (3-5 yrs) |

| Data Captured | Location, Ignition, Engine Hours | Fault Codes, Fuel, RPM, Temps | Location (Periodic) |

| Installation | Simple (3-wire) | Professional Recommended | DIY (Magnetic/Bolt) |

| Primary Use | Maintenance & Utilization | Deep Diagnostics & Health | Theft Recovery & Non-Powered |

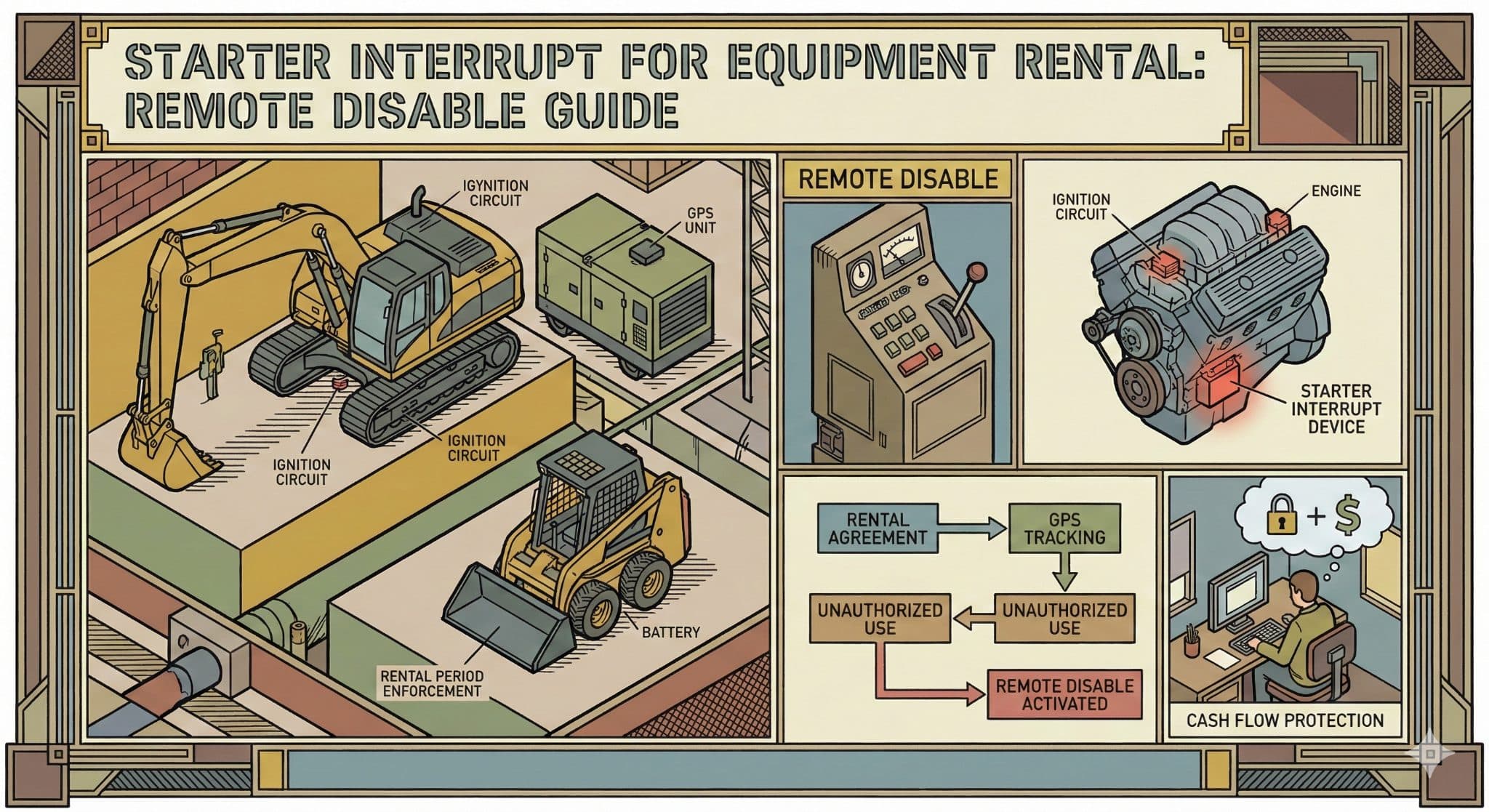

The Case for Redundant Tracking (The "Ghost" Strategy)

Professional thieves are sophisticated. When they steal a piece of yellow iron, the first thing they do is check the standard installation spots (under the dashboard, near the fuse box) for a GPS device. If they find your wired tracker and rip it out, your visibility is gone.

This is why top-tier theft recovery strategies rely on redundancy. We call this the "Ghost" strategy:

- The Decoy/Primary: Install a standard hardwired or telematics device. This handles your daily operations, engine hours, and logistics. It is visible enough that a thief might feel satisfied finding and removing it.

- The Ghost: Hidden deep within the frame or body of the machine is a secondary, battery-powered asset tracker. It wakes up once every 12-24 hours (or more frequently in recovery mode).

If the primary device is disabled, the Ghost unit continues to report. Hapn customers monitor over 463,000 assets, and we have seen numerous recoveries occur specifically because the thieves assumed they had "cleaned" the machine after removing the obvious tracker. This redundancy acts as an affordable insurance policy for assets worth $50,000 to $500,000.

Why Maintenance Integration Matters More Than Location

While location prevents theft, maintenance data prevents bankruptcy. For equipment rental companies and construction firms, maximizing the lifespan of an asset is where the profit margin lives.

Engine Hour-Based Scheduling

Servicing equipment based on calendar dates is inefficient. A generator might sit idle for three weeks and then run 24/7 for a week. Servicing it "monthly" means you are either over-servicing (wasting money on oil and filters) or under-servicing (risking engine failure).

Hapn's platform pulls actual runtime data to trigger alerts: "Unit #405 has reached 480 hours. Service due at 500." This approach ensures compliance with warranty requirements without unnecessary spend. As we covered in our guide to fleet tracking ROI, this shift alone can save 10-15% on maintenance consumables annually. For a deeper dive on implementation, read our guide on engine hour-based maintenance scheduling.

Fault Code Monitoring

Modern telematics devices capture Diagnostic Trouble Codes (DTCs). If a skid steer throws a code for low hydraulic pressure, your maintenance manager gets an alert instantly. They can diagnose the severity remotely before dispatching a field mechanic, ensuring the mechanic arrives with the right parts—or determining if the machine needs to be pulled from the job site immediately to prevent catastrophic failure.

API Integration for Unification

Data silos kill efficiency. If your GPS data lives in one app and your maintenance schedule lives in another, your team is wasting hours on manual entry. The best GPS trackers offer an open API to push engine hours, odometer readings, and fault codes directly into your ERP or maintenance software (like Fleetio or proprietary systems). This eliminates double-entry errors and ensures your billing department always has the exact usage data needed for invoicing, often adhering to the AEMP telematics standard for mixed fleet data unification.

Stop Guessing. Start Tracking.

See how Hapn gives you complete visibility across your mixed fleet — vehicles, equipment, and assets in one platform. No contracts, transparent pricing.

Get Pricing →Key Features to Prioritize in 2026

Not all trackers are built for the job site. When evaluating hardware, look beyond the price tag to these critical specifications.

Real-Time Location & Update Frequency

The "ping rate"—how often the device reports its location—matters immensely.

- 10 to 30-Second Pings: Necessary for vehicles and active equipment where turn-by-turn history is needed for route analysis or accident reconstruction.

- 2 to 5-Minute Pings: Sufficient for slow-moving heavy equipment like bulldozers or pavers.

- Daily Check-Ins: Adequate for stationary assets like dumpsters.

Ensure your provider allows you to adjust these rates. High-frequency tracking provides better data but consumes more data/power; lower frequency is cheaper but less granular. Hapn's platform allows for flexible configuration based on asset type.

Cellular vs. Satellite Coverage

Construction doesn't always happen near a cell tower.

- Cellular (4G/LTE/5G): The most cost-effective solution for urban and suburban sites. It transmits large amounts of data (like video or heavy diagnostics) quickly.

- Satellite: Essential for remote logging, oil/gas, or pipeline projects in dead zones. Satellite data is more expensive and slower, typically used for location coordinates only.

- Hybrid: The best robust solution uses a device that defaults to cellular but switches to satellite automatically when the network drops. This ensures you never lose sight of a six-figure asset just because it moved to a remote quarry.

Tamper Detection & Disconnect Alerts

If a tracker loses power, you need to know why. A quality hardwired tracker should have a small internal backup battery. If the main power is cut (e.g., a thief snips the wires), the device uses its reserve power to send a "Power Disconnect" alert immediately, stamping the location and time. This is often the specific alert that triggers a successful police recovery response.

Durability & Environmental Ratings

Construction sites are brutal environments. Your device must carry at least an IP67 rating. This code indicates the device is completely dust-tight (the '6') and can withstand immersion in water up to 1 meter (the '7'), as defined by the IEC standards. Anything less will eventually fail due to vibration, dust ingress, or pressure washing.

Installation: DIY vs. Professional

When selecting the best GPS tracker for heavy equipment, installation complexity is a major factor in your total cost of ownership.

When to DIY

If you are using simple hardwired trackers (3-wire: red/power, black/ground, white/ignition) or battery-powered units, self-installation is entirely viable. Most fleet mechanics can install a hardwired unit in 15–20 minutes. Battery units take seconds to magnetically mount or bolt on.

This approach saves money upfront but requires you to manage the quality assurance. Poorly crimped wires or loose grounds are the #1 cause of "device failure."

When to Hire Pros

For telematics integration involving the CAN bus, professional installation is highly recommended. Heavy equipment uses different protocols (J1939, J1708) compared to passenger vehicles (OBDII). Incorrectly splicing into an ECU harness can void equipment warranties or cause electrical faults that shut down the machine.

Additionally, for large fleets (50+ assets), the logistical cost of pulling your own mechanics off billable repair work to install trackers often outweighs the cost of a professional rollout.

What to Expect: Costs & ROI

Budgeting for fleet tracking requires looking at three cost buckets: Hardware, Service, and Installation. At Hapn, we believe in transparent pricing with no long-term contracts, a rarity in an industry known for locking customers into 36-month agreements.

1. Hardware Costs

- Simple Wired Trackers: Typically range from $50 to $150 per unit. These are cost-effective for mixed fleets where you need volume coverage.

- Telematics Devices: Expect to pay $150 to $400+ per unit. The higher cost reflects the complex internal components needed to read and interpret ECU data protocols.

- Battery-Powered/Asset Trackers: Usually $75 to $200 per unit depending on battery size (3-year vs 7-year life).

2. Monthly Service Fees

This covers the cellular data plan and software access.

- Basic Tracking: $15 - $30/month per device.

- Advanced Telematics: $25 - $50+/month per device, depending on the depth of diagnostic data and update frequency required.

3. Installation Costs

- DIY: $0 (cost of your mechanic's time).

- Professional Install: $50 - $200 per unit. Complex heavy equipment often sits at the higher end of this range due to the difficulty of accessing power and ignition sources behind reinforced panels.

The ROI Equation

Despite the upfront cost, the ROI is often realized in under a year.

- Theft Recovery: Recovering a single $80,000 excavator pays for tracking on a 50-vehicle fleet for years.

- Downtime Prevention: Unplanned downtime costs an estimated $1,000 to $5,000 per day depending on the machine. Preventing just one major breakdown via fault code alerts covers the system's cost.

- Insurance Discounts: Many carriers offer 5-15% premium reductions for GPS-tracked fleets.

- Utilization: Increasing fleet utilization by just 10% (by identifying idle assets) allows you to take on more jobs without buying more equipment.

In fact, 45% of fleet managers report a positive ROI within 11 months of implementation.

Decision Framework: Which Tracker Do You Need?

Use this simple framework to select the right hardware for your specific assets:

- You need Simple Wired Trackers if: You want to verify billing hours, schedule basic maintenance, and track location on powered equipment like lighting towers, small generators, and older skid steers.

- You need Telematics if: You manage high-value, modern equipment (Tier 4 engines) and need to reduce fuel burn, monitor fault codes, and manage driver behavior.

- You need Battery-Powered if: You are tracking trailers, dumpsters, attachments, or need a "Ghost" backup for high-risk assets.

- You need a Mixed Solution if: You have a diverse fleet. The best platforms allow you to mix and match all three hardware types on a single dashboard.

Frequently Asked Questions

Below are the most common questions fleet managers ask when evaluating heavy equipment tracking solutions.

What is the difference between a GPS tracker and a telematics system?

A basic GPS tracker provides location and often engine hours for maintenance. A telematics system connects to your equipment's onboard computer (ECU) to provide deep diagnostic data like fault codes, fuel levels, idle time, and oil pressure. Telematics is best for proactive maintenance, while basic GPS is ideal for location and billing.

Do GPS trackers work on remote job sites without cell service?

Most standard GPS trackers rely on cellular networks (4G/LTE). However, for remote operations, Hapn offers hybrid satellite/cellular devices. These units transmit data via satellite when cellular networks are unavailable, ensuring you never lose visibility of your assets regardless of location.

Can I track both my equipment and my trucks in one platform?

Yes. A unified platform is essential for modern operations. You should be able to view your yellow iron, your trailers, and your commercial vehicles on a single map. This unification simplifies logistics, allowing dispatchers to see which flatbed is closest to which excavator for pickup. To understand how construction companies use this approach to manage mixed fleets, see our comprehensive guide on GPS tracking for construction equipment.

Can I install heavy equipment GPS trackers myself?

Yes, for simple hardwired trackers (3-wire connection) and battery-powered units, DIY installation is common and takes about 15-20 minutes. However, for advanced telematics that integrate with the equipment's CAN bus system, professional installation is recommended to ensure data accuracy and preserve equipment warranties.

Will GPS tracking lower my equipment insurance premiums?

Yes, many insurance providers offer premium reductions of 5-15% for fleets that utilize GPS tracking, as it significantly aids in theft recovery. Additionally, providing data on driver behavior and safety protocols can further reduce liability costs.

How accurate are engine hours from a GPS tracker?

Hapn's hardwired devices track engine hours by monitoring the ignition status or vibration, providing accuracy within minutes. For telematics devices connected to the ECU, the engine hours are pulled directly from the machine's odometer/meter, ensuring 100% synchronization with the equipment's internal records.

Can I integrate GPS data with my maintenance software?

Absolutely. Leading platforms offer open APIs to push odometer readings and engine hours directly into maintenance software like Fleetio, Dossier, or proprietary ERPs. This automation eliminates manual data entry errors and ensures service intervals are never missed.

What happens if a thief cuts the wires to the tracker?

High-quality hardwired trackers include an internal backup battery. If external power is cut, the device sends an immediate "Power Disconnect" alert with its location. For higher security, we recommend the "Ghost" strategy: hiding a secondary battery-powered tracker on the asset that operates independently of the machine's power.

Is there a monthly fee for GPS tracking?

Yes, GPS tracking requires a cellular data connection to transmit information to the cloud, similar to a cell phone plan. This fee covers the data connectivity and access to the software platform. Hapn offers transparent, contract-free pricing for these services.

How long do battery-powered trackers last?

Battery life depends on the check-in frequency. A device set to report once a day can last 3-5 years or more. If you increase the frequency to real-time tracking during a theft recovery, the battery will deplete faster. Most modern units allow you to change these settings remotely.

Written by the Hapn Team

Hapn provides GPS fleet and asset tracking for 50,000+ customers across construction, equipment rental, and 50+ other industries. Our platform processes over 4 billion messages annually with 99.9% uptime and maintains a 4.8/5 rating across 11,300+ reviews.

Protect Your Fleet Today

Don't wait for a theft or breakdown to upgrade your tracking. Get a custom quote for your mixed fleet today.

Request Pricing →