Key Takeaways

- Nearly 40% of new equipment orders now take over a year to fulfill; 50% take 6-12 months

- Preventative maintenance based on equipment hours prevents premature deterioration and extends fleet life

- 1,000 pieces of heavy equipment are stolen monthly with only 20% recovery rates without protection

- GPS tracking provides tamper alerts, ghost tracker redundancy, and renter accountability features

- Early equipment ordering and proactive maintenance maximize rental revenue during supply shortages

If you're planning on refreshing your fleet or adding some new equipment to your rental lineup, you better get that order in ASAP.

A recent poll of Construction Equipment Rental professionals shows that nearly 40% of all new orders are taking manufacturers over a year to fulfill. Almost 50% of respondents stated that fulfillment is taking somewhere between 6 to 12 months.

Considering these extreme wait times, there are a few tactics your shop can follow to navigate these challenging times.

How To Stay Ahead of Long Fulfillment Times at Your Rental Shop

1. Improve the Scheduling & Timing of Preventative Maintenance

The success of your shop rests on your ability to maximize the life of your fleet. With preventative maintenance your key weapon in this fight, it's critical you schedule preventative maintenance with certainty.

Many shops run a simple calculation based on the number of days an item was out in the field, but this leaves some guesswork that can result in negative outcomes:

- You conduct maintenance too soon, leading to wasted costs on parts & labor, and lost rental revenue while the equipment is in the shop.

- You conduct maintenance too late, which, over time, leads to an item that reaches the end of its life prematurely.

Having GPS trackers on your equipment that provide the hours of movement is critical to pinpoint the exact moment your inventory needs preventative maintenance. Learn more about engine hour-based maintenance optimization.

2. Submit Your Orders Early

As budgets and margins are getting tighter, it's critical to plan ahead and place your order as soon as possible. As demand for equipment grows in the Spring and Summer, it's critical that your equipment is on track to arrive in the same window of time.

Waiting until April to order a skid steer needed in July simply won't cut it.

Check with your dealer on lead times for the items you'll need next year, and get in line now, if necessary.

See How Hapn Works for Your Fleet

Manage your rental equipment inventory efficiently and protect your assets from theft.

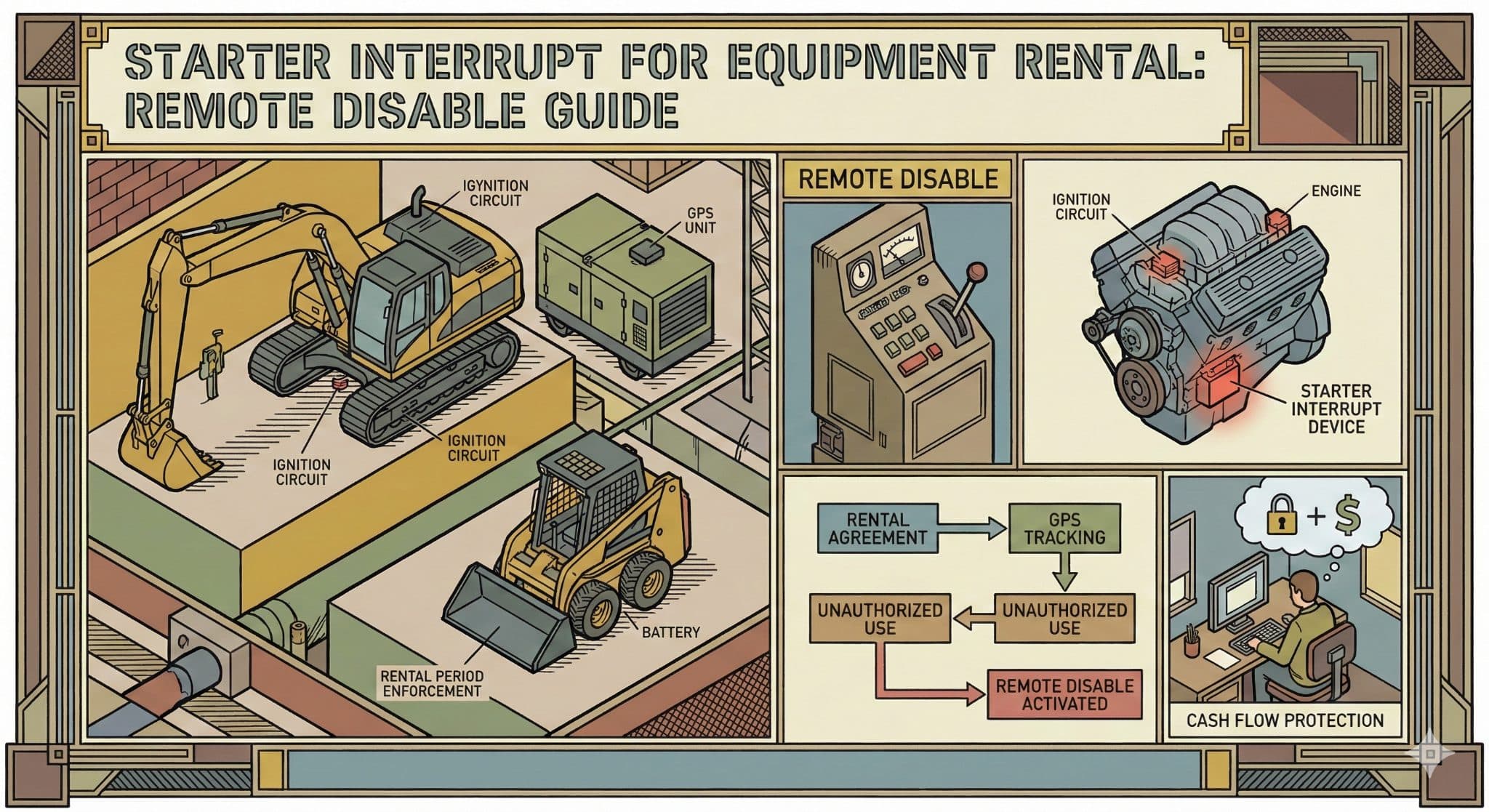

Get Started Today3. Protect Your Equipment From Loss

The National Insurance Crime Bureau estimates that 1,000 pieces of heavy equipment are stolen each month. With a recovery rate of only 20%, the odds of recovering your equipment are not in your favor.

Even if insurance covers the entire price for a replacement, you're still without rental revenue for the entire time it takes to purchase a new item ‑ which, as noted above, is taking over a year for 40% of all new orders.

Using GPS trackers on your rental equipment is not only a great way to manage inventory, but it can also help in the recovery of equipment that was stolen or gone missing. Explore GPS tracking solutions for construction equipment.

Beyond basic GPS services, Hapn offers features that are ideal for the construction rental industry:

- Trackers with tamper alerts to let you know if a tracker has been removed

- Secondary "ghost trackers" begin tracking if the main unit is removed

- Location sharing with renters via a simple web link to help coordinate delivery and add accountability to renters. Learn about fleet utilization best practices.

Beyond theft prevention, understand total cost of ownership and best heavy equipment tracking solutions to make data-driven decisions.

Interested in learning about Hapn's GPS tracking system and how it can streamline operations? Click here to connect with our team.

Frequently Asked Questions

How long should I wait to order equipment for next season?

With 40% of orders taking over a year and 50% taking 6-12 months, you should place orders 12-18 months in advance for Spring/Summer demand. Contact your dealers now to check specific lead times for the equipment you'll need.

What's the best way to schedule preventative maintenance?

Track equipment operating hours rather than calendar days. This prevents both premature maintenance (wasting money) and delayed maintenance (shortening equipment life). GPS trackers provide this data automatically. Learn about geofence capabilities to monitor equipment location during maintenance.

How effective is GPS tracking for theft recovery?

While overall recovery is only 20%, GPS-equipped equipment is recovered at significantly higher rates. Tamper alerts and ghost trackers dramatically improve recovery chances by preventing permanent loss.

Can I share equipment location with renters?

Yes. Hapn provides location sharing via simple web links that don't require renter login. This improves delivery coordination, adds accountability, and reduces disputes while protecting your data security.

How much revenue can I lose if equipment is stolen?

Beyond the equipment value, you lose rental revenue for the entire replacement period (12+ months given current delays). A single $50,000 excavator at $500/month rental = $6,000+ lost revenue per month. GPS protection pays for itself quickly.

Protect Your Rental Fleet Today

Navigate equipment shortages and theft risks with Hapn's comprehensive tracking and management solutions.

Begin Your Free Trial