Stop Portal-Hopping: How AEMP Compliance Unifies Your Mixed Fleet Data

"I didn't know Hapn supports AEMP."

If you've thought this, you're definitely not alone. Here's the thing: if you're running a mixed fleet, your machines are already streaming rich data from OEM telematics systems. The problem isn't lack of data—it's that the data is scattered across multiple portals, making it nearly impossible to get a complete picture of your operations.

That's where Hapn's AEMP compliance changes the game. We pull that factory data in via AEMP (ISO 15143-3), normalize it, and make it work seamlessly alongside your aftermarket devices. Same map, same rules, same reports. No more portal-hopping required.

Last updated: February 2026

Key Takeaways

- Hapn monitors 463,000+ assets across 50+ industries with 99.9% uptime

- AEMP (ISO 15143-3) standardizes how OEMs share fleet data, eliminating the need for separate portals

- Portal-hopping across Caterpillar, John Deere, Komatsu, and aftermarket systems wastes time and hides operational patterns

- Unified fleet tracking enables better utilization insights, proactive maintenance, and transparent customer reporting

- Mixed fleet strategies deliver higher uptime and faster ROI when all data flows through one platform

What is AEMP?

AEMP (Association of Equipment Management Professionals) maintains the ISO 15143-3 telematics standard — a universal data format that allows equipment manufacturers like Caterpillar, John Deere, and Komatsu to share machine data (location, engine hours, fuel levels, fault codes) through a single standardized API, eliminating the need for separate OEM portals.

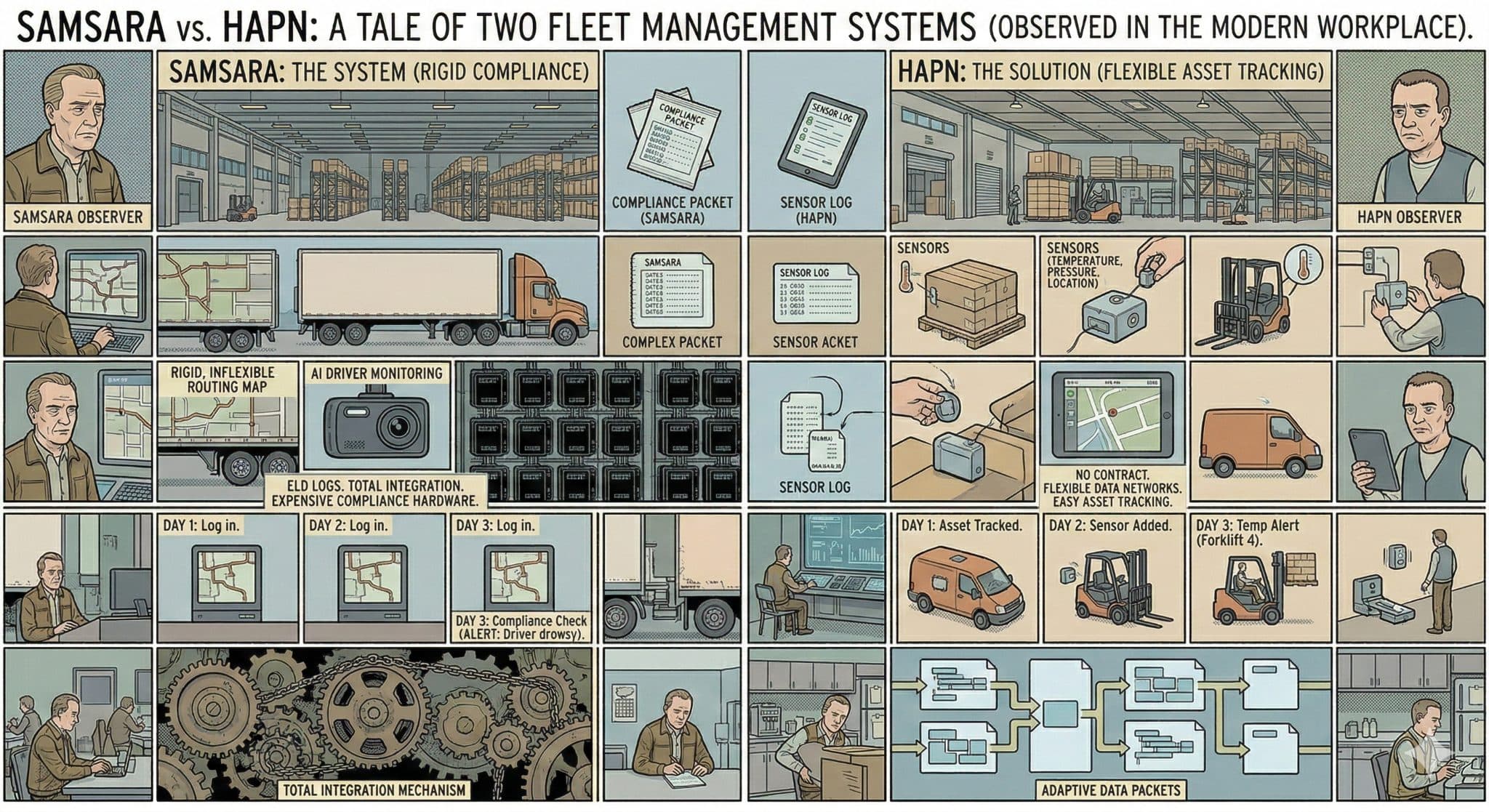

The Reality of Mixed Fleet Management

Every rental and construction team knows the pain: you've got Caterpillar machines reporting through VisionLink, John Deere equipment in JDLink, aftermarket telematics on various other platforms, and suddenly you're managing five different logins just to understand what's happening across your fleet. Every extra portal costs time and hides the patterns you need to see to run an efficient operation.

With Hapn's AEMP integration, you finally get what you've been looking for: a single source of truth across all your branches and projects. Less swivel-chair time jumping between systems, cleaner handoffs when sharing views with customers and field teams, and fewer surprises because issues and maintenance needs trigger alerts before they burn a day on the jobsite.

Understanding AEMP in Plain English

Let's cut through the technical jargon for a moment. AEMP is simply the common language that OEMs use to publish fleet data. Think of it as a universal translator—instead of each manufacturer speaking their own dialect, AEMP creates a standardized way for all these systems to communicate the same types of information.

Hapn speaks this language fluently. We map those standardized fields into Hapn objects so your OEM units behave exactly like any other device in your system. The typical data you'll see via AEMP includes location and timestamps, engine hours and odometer readings, fuel levels and consumption, idle status and machine states, plus diagnostic and fault codes when the OEM provides them.

What This Means for Your Daily Operations

The real power of AEMP compliance isn't in the technical specs—it's in what you can actually do with unified data. Imagine opening one platform and seeing your live map with both OEM and aftermarket assets together. You can reconstruct the timeline of any day, week, or entire job without jumping between systems.

But visibility is just the starting point. The real value comes from being able to act on this unified data through intelligent alerts and policies. Set utilization thresholds to flag assets that aren't meeting target hours by class or branch. Get notified when machines idle too long inside specific geofences. Track enter and exit times for jobsites, monitor after-hours movement, and even get alerts for state line crossings. When it comes to maintenance, you can trigger work orders automatically when assets hit hour intervals or critical fault thresholds.

And when it's time to prove value—whether to your customers or your own management—you'll have the reports to back it up. Engine hours by jobsite and customer for billing validation, utilization rollups by class and model, idle time analysis with estimated fuel impact, and comprehensive fault trends and service tracking.

Three Quick Wins You Can Implement Today

Once you've got your OEM data flowing into Hapn, there are three immediate wins that take about ten minutes each to set up but deliver ongoing value:

Customer Transparency: Create a read-only view of any jobsite that you can share with renters. They'll see exactly what equipment is on rent and working in real-time, which builds trust and reduces those "is my machine actually working?" phone calls.

Revenue Protection: Use geofences (we call them boundaries) combined with hour tracking to validate on-rent and off-rent timing. No more disputes about when equipment was actually returned or put to work.

Proactive Uptime: Auto-create work orders when critical faults appear or when machines hit service intervals like 250 hours. Catch issues before they become expensive downtime. For specific equipment types like scissor lifts and boom lifts, maintenance scheduling ensures safe operation and extends asset lifespan. Additionally, understanding how to effectively track assets ensures you're capturing all the operational insights needed for proactive maintenance decisions.

See Your Entire Fleet on One Screen

Stop logging into five different OEM portals. Hapn unifies your diesel, electric, and mixed fleet data with AEMP compliance built in. No contracts, transparent pricing.

Get Pricing →How It Actually Works in Practice

Inside Hapn, your OEM machines appear on the map and in lists with clear labels, status indicators, and last-seen timestamps. Each asset gets a comprehensive profile page showing hours, recent faults, activity history, plus any files, photos, and notes your team has added—all in one place.

The policy builder lets you create human-readable rules without needing to understand complex logic. Something like "Telehandlers at Branch A must not idle more than 15 minutes on weekdays" is exactly how you'd write it. Reports can be scheduled automatically—maybe a weekly utilization summary by equipment class, or a daily idle exception report that highlights problems.

Maintenance management becomes streamlined with hour-based schedules that include assignees, checklists, and complete service history. Everything you need to keep your fleet running smoothly.

Getting Started Is Simpler Than You Think

The setup process is designed to minimize disruption to your current operations. First, you'll select which OEMs you're currently using from our supported list (we work with dozens across earthmoving, access, compact, and power equipment—just ask us for the current roster). Then you'll connect your credentials or authorized access for each OEM portal.

The asset matching happens through VIN or serial number, and we help automate this mapping process. Once that's complete, you can immediately start building policies and reports using the same interface you'd use for any other equipment. No retraining required for your team.

Our equipment rental platform streamlines the entire rental workflow, from asset tracking to billing validation. When combined with AEMP compliance, you get complete visibility across your entire rental fleet lifecycle. For deeper insights into asset management, explore our guides on how asset tracking works and different asset tracking types for professional services. Additionally, electric and hybrid equipment support means you can manage modern fleets across all fuel types on a single unified dashboard.

Important Details to Keep in Mind

Data freshness follows whatever cadence each OEM provides—some update every few minutes, others might be hourly or longer intervals. Hapn shows the last-updated timestamp everywhere so you always know how current your information is.

The beauty of the system is that you can mix OEM and aftermarket devices in the same geofences, policies, dashboards, and reports. Your team and customers can be brought in with appropriate roles and permissions, so everyone sees exactly what they need to see.

If you're debating whether to adopt OEM or aftermarket tracking, we've covered the full spectrum in our guide on OEM telematics vs. aftermarket GPS solutions. The short answer: you don't have to choose when you use a unified platform like Hapn.

Clearing up Common Misconceptions

There are a couple of myths worth addressing. First, some people think "AEMP means I get everything." The reality is that AEMP standardizes core fields, but certain advanced diagnostics or detailed CAN bus data still depends on what each OEM chooses to share. Hapn shows you exactly what's available and lets you act on it.

Second, there's often concern about needing "duplicate devices." If your factory telematics unit already covers your tracking needs, just use it. You only need to add aftermarket devices where you want higher update frequency, recovery capabilities, or specialized sensors that aren't built into the OEM system. For comprehensive theft prevention, dual-layer GPS tracking with ghost trackers ensures you can recover high-value assets even when primary trackers are disabled.

Frequently Asked Questions

Which OEMs are supported?

We integrate with dozens of manufacturers across all the major categories. Rather than maintaining a static list here, it's better to ask us directly for the current roster—or tell us which OEMs to prioritize if you don't see yours.

How often does data update?

This varies by manufacturer, but Hapn surfaces last-seen timestamps clearly and supports on-demand refresh where the OEM allows it.

Do alerts and reports work on OEM data?

Absolutely. Once connected, OEM feeds behave exactly like any other data source in your policies and reporting.

Can I share views with customers?

Yes, you can create customer-specific groups and send shareable views or set up scheduled reports that go directly to them.

What's the best way to unify OEM telematics data?

Use a platform like Hapn that natively supports AEMP (ISO 15143-3) compliance. This allows you to connect all major OEM systems through a single API integration, eliminating manual data consolidation and portal-hopping.

Does Hapn support AEMP ISO 15143-3?

Yes, AEMP compliance is built into Hapn's platform. We support all standard ISO 15143-3 data fields and work with your OEMs to enable data sharing through our secure API infrastructure.

Written by the Hapn Team

Hapn provides GPS fleet and asset tracking for 50,000+ customers across construction, equipment rental, and 50+ other industries. Our platform monitors 463,000+ assets and processes over 4 billion messages annually with 99.9% uptime.

The Bottom Line

Your fleet is already talking—through factory telematics, aftermarket devices, and various other systems. Hapn makes all that chatter actually useful by bringing it together in one place. Connect your OEM portals once, then run your entire operation from a single dashboard. Utilization tracking, maintenance scheduling, billing validation, and customer transparency all become part of your daily workflow instead of separate headaches.

Ready to see how your OEM data can work better for you? Get in touch with the Hapn team for a current OEM compatibility list and a guided setup that'll have you up and running faster than you might expect.

Stop Portal-Hopping. Start Managing.

Connect your OEM data, unify your fleet view, and run everything from one platform. No contracts, transparent pricing.

Get Pricing →